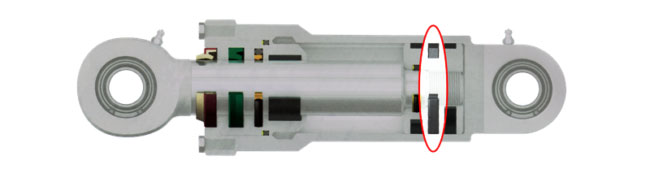

Piston seal maintain sealing contact in sliding motion between the piston and cylinder bore.

Differential pressures acting on the piston to extend or retract the piston rod can be in excess of 400 bar (5,800 psi). The pressure acting on the piston seal increases contact forces between the piston and cylinder surface. Therefore the surface properties of the sealing surfaces are critical to proper seal performance.

Piston seals are typically classified into single acting (pressure acting on one side only) and double acting (pressure acting on either side) seals.

Sealing Australia stocks the following profiles:

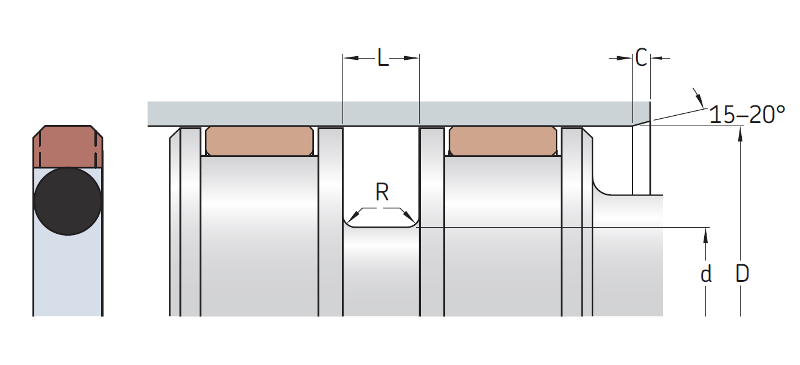

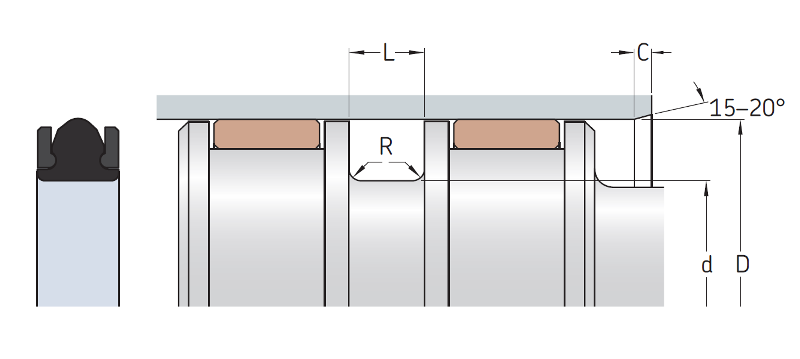

GH and GHM profiles have a nitrile (NBR) rubber o’ring energiser and a bronze filled PTFE sealing element. Square ring and Viton energiser are available on request. There profiles are suitable for pressures up to 400 bar (5,800 psi) and are available in metric sizes. Some metric sizes fit seal housing in accordance to ISO 7425-1.

| Part No | (D) ± H9 | (d) ± h9 | (L) ±0.05 | (C) min |

|---|---|---|---|---|

| GHM-10*5.1*2.2 | 10.0 | 5.1 | 2.2 | 3.0 |

| GHM-12*7.1*2.2 | 12.0 | 7.1 | 2.2 | 3.0 |

| GHM-15*7.5*3.2 | 15.0 | 7.5 | 3.2 | 5.0 |

| GHM-16*8.5*3.2 | 16.0 | 8.5 | 3.2 | 5.0 |

| GHM-18*10.5*3.2 | 18.0 | 10.5 | 3.2 | 5.0 |

| GHM-20*12.5*3.2 | 20.0 | 12.5 | 3.2 | 5.0 |

| GHM-22*14.5*3.2 | 22.0 | 14.5 | 3.2 | 5.0 |

| GHM-25*17.5*3.2 | 25.0 | 17.5 | 3.2 | 5.0 |

| GHM-28*20.5*3.2 | 28.0 | 20.5 | 3.2 | 5.0 |

| GHM-30*22.5*3.5 | 30.0 | 22.5 | 3.2 | 5.0 |

| GHM-32*24.5*3.2 | 32.0 | 24.5 | 3.2 | 5.0 |

| GHM-35*27.5*3.2 | 35.0 | 27.5 | 3.2 | 5.0 |

| GHM-36*28.5*3.2 | 36.0 | 28.5 | 3.2 | 5.0 |

| GHM-40*29*4.2 | 40.0 | 29.0 | 4.2 | 7.0 |

| GHM-40*32.5*3.2 | 40.0 | 32.5 | 3.2 | 5.0 |

| GHM-42*31*4.2 | 42.0 | 31.0 | 4.2 | 7.0 |

| GHM-45*34*4.2 | 45.0 | 34.0 | 4.2 | 7.0 |

| GHM-48*37*4.2 | 48.0 | 37.0 | 4.2 | 7.0 |

| GHM-50*39*4.2 | 50.0 | 39.0 | 4.2 | 7.0 |

| GHM-55*44*4.2 | 55.0 | 44.0 | 4.2 | 7.0 |

| GHM-60*49*4.2 | 60.0 | 49.0 | 4.2 | 7.0 |

| GHM-63*52*4.2 | 63.0 | 52.0 | 4.2 | 7.0 |

| GHM-65*54*4.2 | 65.0 | 54.0 | 4.2 | 7.0 |

| GHM-70*54.5*6.3 | 70.0 | 54.5 | 6.3 | 10.0 |

| GHM-70*59*4.2 | 70.0 | 59.0 | 4.2 | 7.0 |

| GHM-75*59.5*6.3 | 75.0 | 59.5 | 6.3 | 10.0 |

| GHM-75*64*4.2 | 75.0 | 64.0 | 4.2 | 7.0 |

| GHM-80*59*8.1 | 80.0 | 59.0 | 8.1 | 12.0 |

| GHM-80*64.5*6.3 | 80.0 | 64.5 | 6.3 | 10.0 |

| GHM-80*69*4.2 | 80.0 | 69.0 | 4.2 | 7.0 |

| GHM-85*64*8.1 | 85.0 | 64.0 | 8.1 | 12.0 |

| GHM-85*69.5*6.3 | 85.0 | 69.5 | 6.3 | 10.0 |

| GHM-90*69*8.1 | 90.0 | 69.0 | 8.1 | 12.0 |

| GHM-90*74.5*6.3 | 90.0 | 74.5 | 6.3 | 10.0 |

| GHM-95*74*8.1 | 95.0 | 74.0 | 8.1 | 12.0 |

| GHM-95*79.5*6.3 | 95.0 | 79.5 | 6.3 | 10.0 |

| GHM-100*79*8.1 | 100.0 | 79.0 | 8.1 | 12.0 |

| GHM-100*84.5*6.3 | 100.0 | 84.5 | 6.3 | 10.0 |

| GHM-105*89.5*6.3 | 105.0 | 89.5 | 6.3 | 10.0 |

| GHM-110*89*8.1 | 110.0 | 89.0 | 8.1 | 12.0 |

| GHM-110*94.5*6.3 | 110.0 | 94.5 | 6.3 | 10.0 |

| GHM-115*99.5*6.3 | 115.0 | 99.5 | 6.3 | 10.0 |

| GHM-120*99*8.1 | 120.0 | 99.0 | 8.1 | 12.0 |

| GHM-120*104.5*6.3 | 120.0 | 104.5 | 6.3 | 10.0 |

| GHM-125*104*8.1 | 125.0 | 104.0 | 8.1 | 12.0 |

| GHM-125*109.5*6.3 | 125.0 | 109.5 | 6.3 | 10.0 |

| GHM-130*109*8.1 | 130.0 | 109.0 | 8.1 | 12.0 |

| GHM-130*114.5*6.3 | 130.0 | 114.5 | 6.3 | 10.0 |

| GHM-135*114*8.1 | 135.0 | 114.0 | 8.1 | 10.0 |

| GHM-140*119*8.1 | 140.0 | 119.0 | 8.1 | 12.0 |

| GHM-145*124*8.1 | 145.0 | 124.0 | 8.1 | 12.0 |

| GHM-150*129*8.1 | 150.0 | 129.0 | 8.1 | 12.0 |

| GHM-155*134*8.1 | 155.0 | 134.0 | 8.1 | 12.0 |

| GHM-160*139*8.1 | 160.0 | 139.0 | 8.1 | 12.0 |

| GHM-165*144*8.1 | 165.0 | 144.0 | 8.1 | 12.0 |

| GHM-170*149*8.1 | 170.0 | 149.0 | 8.1 | 12.0 |

| GHM-180*159*8.1 | 180.0 | 159.0 | 8.1 | 12.0 |

| GHM-190*169*8.1 | 190.0 | 169.0 | 8.1 | 12.0 |

| GHM-200*179*8.1 | 200.0 | 179.0 | 8.1 | 12.0 |

| GHM-210*189*8.1 | 210.0 | 189.0 | 8.1 | 12.0 |

| GHM-220*199*8.1 | 220.0 | 199.0 | 8.1 | 12.0 |

| GHM-230*209*8.1 | 230.0 | 209.0 | 8.1 | 12.0 |

| GHM-240*219*8.1 | 240.0 | 219.0 | 8.1 | 12.0 |

| GHM-250*229*8.1 | 250.0 | 229.0 | 8.1 | 12.0 |

| GHM-260*239*8.1 | 260.0 | 239.0 | 8.1 | 12.0 |

| GHM-280*259*8.1 | 280.0 | 259.0 | 8.1 | 12.0 |

| GHM-300*279*8.1 | 300.0 | 279.0 | 8.1 | 12.0 |

| GHM-320*299*8.1 | 320.0 | 299.0 | 8.1 | 12.0 |

| GHM-340*315.5*8.1 | 340.0 | 315.5 | 8.1 | 16.0 |

| GHM-350*325.5*8.1 | 350.0 | 325.5 | 8.1 | 16.0 |

| GHM-360*335.5*8.1 | 360.0 | 335.5 | 8.1 | 16.0 |

| GHM-370*345.5*8.1 | 370.0 | 345.5 | 8.1 | 16.0 |

| GHM-380*355.5*8.1 | 380.0 | 355.5 | 8.1 | 16.0 |

| GHM-400*375.5*8.1 | 400.0 | 375.5 | 8.1 | 16.0 |

| GHM-500*475.5*8.1 | 500.0 | 475.5 | 8.1 | 16.0 |

| Part No | (D) | ± | (d) | ± | (L) ±.002 |

|---|---|---|---|---|---|

| GH0D-500 | 0.500 | +.002 | 0.240 | ±.002 | 0.083 |

| GH0A-500 | 0.500 | +.002 | 0.326 | ±.001 | 0.083 |

| GH0D-562 | 0.562 | +.002 | 0.302 | ±.002 | 0.083 |

| GH0A-562 | 0.562 | +.002 | 0.388 | ±.001 | 0.083 |

| GH0D-625 | 0.625 | +.002 | 0.625 | ±.002 | 0.083 |

| GH0A-625 | 0.625 | +.001 | 0.451 | ±.001 | 0.083 |

| GH1A-687 | 0.687 | +.002 | 0.389 | ±.001 | 0.128 |

| GH0D-687 | 0.687 | +.002 | 0.427 | ±.002 | 0.083 |

| GH0A-687 | 0.687 | +.002 | 0.513 | ±.001 | 0.083 |

| GH1A-750 | 0.750 | +.002 | 0.452 | ±.001 | 0.128 |

| GH0D-750 | 0.750 | +.002 | 0.490 | ±.002 | 0.083 |

| GH0A-750 | 0.750 | +.002 | 0.576 | ±.001 | 0.083 |

| GH1A-812 | 0.812 | +.002 | 0.514 | ±.001 | 0.128 |

| GH0D-812 | 0.812 | +.002 | 0.552 | ±.002 | 0.083 |

| GH0A-812 | 0.812 | +.002 | 0.638 | ±.002 | 0.083 |

| GH1A-875 | 0.875 | +.002 | 0.577 | ±.001 | 0.128 |

| GH0D-875 | 0.875 | +.002 | 0.615 | ±.002 | 0.083 |

| GH0A-875 | 0.875 | +.002 | 0.701 | ±.001 | 0.083 |

| GH1A-937 | 0.937 | +.002 | 0.639 | ±.001 | 0.128 |

| GH0D-937 | 0.937 | +.002 | 0.677 | ±.002 | 0.083 |

| GH0A-937 | 0.937 | +.002 | 0.763 | ±.001 | 0.083 |

| GH1A-1000 | 1.000 | +.002 | 0.702 | ±.001 | 0.128 |

| GH0D-1000 | 1.000 | +.002 | 0.740 | ±.002 | 0.083 |

| GH0A-1000 | 1.000 | +.002 | 0.826 | ±.001 | 0.083 |

| GH1A-1062 | 1.062 | +.002 | 0.764 | ±.001 | 0.128 |

| GH0D-1062 | 1.062 | +.002 | 0.802 | ±.002 | 0.083 |

| GH0A-1062 | 1.062 | +.002 | 0.888 | ±.001 | 0.083 |

| GH1A-1125 | 1.125 | +.002 | 0.827 | ±.001 | 0.128 |

| GH0D-1125 | 1.125 | +.002 | 0.865 | ±.002 | 0.083 |

| GH0A-1125 | 1.125 | +.002 | 0.951 | ±.001 | 0.083 |

| GH1A-1187 | 1.187 | +.002 | 0.889 | ±.001 | 0.128 |

| GH0D-1187 | 1.187 | +.002 | 0.927 | ±.002 | 0.083 |

| GH0A-1187 | 1.187 | +.002 | 1.013 | ±.001 | 0.083 |

| GH1A-1250 | 1.250 | +.002 | 0.952 | ±.001 | 0.128 |

| GH0D-1250 | 1.250 | +.002 | 0.990 | ±.002 | 0.083 |

| GH0A-1250 | 1.250 | +.002 | 1.076 | ±.001 | 0.083 |

| GH1A-1312 | 1.312 | +.002 | 1.014 | ±.001 | 0.128 |

| GH0D-1312 | 1.312 | +.002 | 1.052 | ±.002 | 0.083 |

| GH0A-1312 | 1.312 | +.002 | 1.138 | ±.001 | 0.083 |

| GH1A-1375 | 1.375 | +.002 | 1.077 | ±.001 | 0.128 |

| GH0D-1375 | 1.375 | +.002 | 1.115 | ±.002 | 0.083 |

| GH0A-1375 | 1.375 | +.002 | 1.201 | ±.001 | 0.083 |

| GH1A-1437 | 1.437 | +.002 | 1.139 | ±.001 | 0.128 |

| GH0D-1437 | 1.437 | +.002 | 1.177 | ±.002 | 0.083 |

| GH0A-1437 | 1.437 | +.002 | 1.263 | ±.001 | 0.083 |

| GH1A-1500 | 1.500 | +.002 | 1.202 | ±.001 | 0.128 |

| GH0D-1500 | 1.500 | +.002 | 1.240 | ±.002 | 0.083 |

| GH0A-1500 | 1.500 | +.002 | 1.326 | ±.001 | 0.083 |

| GH2A-1562 | 1.562 | +.002 | 1.138 | ±.002 | 0.168 |

| GH1D-1562 | 1.562 | +.002 | 1.170 | ±.002 | 0.122 |

| GH1A-1562 | 1.562 | +.002 | 1.264 | ±.001 | 0.128 |

| GH2A-1625 | 1.625 | +.002 | 1.201 | ±.002 | 0.168 |

| GH1D-1625 | 1.625 | +.002 | 1.233 | ±.002 | 0.122 |

| GH1A-1625 | 1.625 | +.002 | 1.327 | ±.001 | 0.128 |

| GH2A-1687 | 1.687 | +.002 | 1.263 | ±.002 | 0.168 |

| GH1D-1687 | 1.687 | +.002 | 1.295 | ±.002 | 0.122 |

| GH1A-1687 | 1.687 | +.002 | 1.389 | ±.001 | 0.128 |

| GH2A-1750 | 1.750 | +.002 | 1.326 | ±.002 | 0.168 |

| GH1D-1750 | 1.750 | +.002 | 1.358 | ±.002 | 0.122 |

| GH1A-1750 | 1.750 | +.002 | 1.452 | ±.001 | 0.128 |

| GH2A-1812 | 1.812 | +.002 | 1.388 | ±.002 | 0.168 |

| GH1D-1812 | 1.812 | +.002 | 1.420 | ±.002 | 0.122 |

| GH1A-1812 | 1.812 | +.002 | 1.514 | ±.001 | 0.128 |

| GH2A-1875 | 1.875 | +.002 | 1.451 | ±.002 | 0.168 |

| GH1D-1875 | 1.875 | +.002 | 1.483 | ±.002 | 0.122 |

| GH1A-1875 | 1.875 | +.002 | 1.577 | ±.001 | 0.128 |

| GH2A-1937 | 1.937 | +.002 | 1.513 | ±.002 | 0.168 |

| GH1D-1937 | 1.937 | +.002 | 1.545 | ±.002 | 0.122 |

| GH1A-1937 | 1.937 | +.002 | 1.639 | ±.001 | 0.128 |

| GH2A-2000 | 2.000 | +.002 | 1.576 | ±.002 | 0.168 |

| GH1D-2000 | 2.000 | +.002 | 1.608 | ±.002 | 0.129 |

| GH1A-2000 | 2.000 | +.002 | 1.702 | ±.001 | 0.128 |

| GH2A-2125 | 2.000 | +.002 | 1.701 | ±.002 | 0.168 |

| GH1D-2125 | 2.125 | +.002 | 1.733 | ±.002 | 0.129 |

| GH1A-2125 | 2.125 | +.002 | 1.827 | ±.001 | 0.128 |

| GH2A-2250 | 2.250 | +.002 | 1.826 | ±.002 | 0.168 |

| GH1D-2250 | 2.250 | +.002 | 1.858 | ±.002 | 0.129 |

| GH1A-2250 | 2.250 | +.002 | 1.952 | ±.001 | 0.128 |

| GH2A-2375 | 2.375 | +.002 | 1.951 | ±.002 | 0.168 |

| GH1D-2375 | 2.375 | +.002 | 1.983 | ±.002 | 0.129 |

| GH1A-2375 | 2.375 | +.002 | 2.077 | ±.001 | 0.128 |

| GH2A-2500 | 2.500 | +.002 | 2.076 | ±.002 | 0.168 |

| GH1D-2500 | 2.500 | +.002 | 2.108 | ±.002 | 0.129 |

| GH1A-2500 | 2.500 | +.002 | 2.202 | ±.001 | 0.128 |

| GH2A-2625 | 2.625 | +.002 | 2.201 | ±.002 | 0.168 |

| GH1D-2625 | 2.625 | +.002 | 2.233 | ±.002 | 0.129 |

| GH1A-2625 | 2.625 | +.002 | 2.327 | ±.001 | 0.128 |

| GH2A-2750 | 2.750 | +.002 | 2.326 | ±.002 | 0.168 |

| GH1D-2750 | 2.750 | +.002 | 2.358 | ±.002 | 0.129 |

| GH1A-2750 | 2.750 | +.002 | 2.452 | ±.001 | 0.128 |

| GH2A-2875 | 2.875 | +.002 | 2.451 | ±.002 | 0.168 |

| GH1D-2875 | 2.875 | +.002 | 2.483 | ±.002 | 0.129 |

| GH1A-2875 | 2.875 | +.002 | 2.577 | ±.001 | 0.128 |

| GH2A-3000 | 3.000 | +.002 | 2.576 | ±.002 | 0.168 |

| GH1D-3000 | 3.000 | +.002 | 2.608 | ±.002 | 0.129 |

| GH1A-3000 | 3.000 | +.002 | 2.702 | ±.001 | 0.128 |

| GH3A-3125 | 3.125 | +.002 | 2.509 | ±.003 | 0.249 |

| GH2A-3125 | 3.125 | +.002 | 2.701 | ±.002 | 0.168 |

| GH1D-3125 | 3.125 | +.003 | 2.733 | ±.002 | 0.129 |

| GH3A-3250 | 3.250 | +.002 | 2.634 | ±.003 | 0.249 |

| GH2A-3250 | 3.250 | +.002 | 2.826 | ±.002 | 0.168 |

| GH1D-3250 | 3.250 | +.003 | 2.858 | ±.002 | 0.129 |

| GH3A-3375 | 3.375 | +.002 | 2.759 | ±.003 | 0.249 |

| GH2A-3375 | 3.375 | +.002 | 2.951 | ±.002 | 0.168 |

| GH1D-3375 | 3.375 | +.003 | 2.983 | ±.002 | 0.129 |

| GH3A-3500 | 3.500 | +.002 | 2.884 | ±.003 | 0.249 |

| GH2A-3500 | 3.500 | +.002 | 3.076 | ±.002 | 0.168 |

| GH1D-3500 | 3.500 | +.003 | 3.108 | ±.002 | 0.129 |

| GH3A-3625 | 3.625 | +.002 | 3.009 | ±.003 | 0.249 |

| GH2A-3625 | 3.625 | +.002 | 3.201 | ±.002 | 0.168 |

| GH1D-3625 | 3.625 | +.003 | 3.233 | ±.002 | 0.129 |

| GH3A-3750 | 3.750 | +.002 | 3.134 | ±.003 | 0.249 |

| GH2A-3750 | 3.750 | +.002 | 3.326 | ±.002 | 0.168 |

| GH1D-3750 | 3.750 | +.003 | 3.358 | ±.002 | 0.129 |

| GH3A-3875 | 3.875 | +.002 | 3.259 | ±.003 | 0.249 |

| GH2A-3875 | 3.875 | +.002 | 3.451 | ±.002 | 0.168 |

| GH1D-3875 | 3.875 | +.002 | 3.483 | ±.002 | 0.129 |

| GH3A-4000 | 4.000 | +.002 | 3.384 | ±.003 | 0.249 |

| GH2A-4000 | 4.000 | +.002 | 3.576 | ±.002 | 0.168 |

| GH1D-4000 | 4.000 | +.003 | 3.608 | ±.002 | 0.129 |

| GH3A-4125 | 4.125 | +.002 | 3.509 | ±.003 | 0.249 |

| GH2A-4125 | 4.125 | +.002 | 3.701 | ±.002 | 0.168 |

| GH1D-4125 | 4.125 | +.003 | 3.733 | ±.002 | 0.129 |

| GH3A-4250 | 4.250 | +.002 | 3.634 | ±.003 | 0.249 |

| GH2A-4250 | 4.250 | +.002 | 3.826 | ±.002 | 0.168 |

| GH1D-4250 | 4.250 | +.003 | 3.858 | ±.002 | 0.129 |

| GH3A-4375 | 4.375 | +.002 | 3.759 | ±.003 | 0.249 |

| GH2A-4375 | 4.375 | +.002 | 3.951 | ±.002 | 0.168 |

| GH1D-4375 | 4.375 | +.003 | 3.983 | ±.002 | 0.129 |

| GH3A-4500 | 4.500 | +.002 | 3.884 | ±.003 | 0.249 |

| GH2A-4500 | 4.500 | +.002 | 4.076 | ±.002 | 0.168 |

| GH1D-4500 | 4.500 | +.003 | 4.108 | ±.002 | 0.129 |

| GH3A-4625 | 4.625 | +.002 | 4.009 | ±.003 | 0.249 |

| GH2A-4625 | 4.625 | +.002 | 4.201 | ±.002 | 0.168 |

| GH1D-4625 | 4.625 | +.003 | 4.233 | ±.002 | 0.129 |

| GH3A-4750 | 4.750 | +.002 | 4.134 | ±.003 | 0.249 |

| GH2A-4750 | 4.750 | +.002 | 4.326 | ±.002 | 0.168 |

| GH1D-4750 | 4.750 | +.003 | 4.358 | ±.002 | 0.129 |

| GH3A-4875 | 4.875 | +.002 | 4.259 | ±.003 | 0.249 |

| GH2A-4875 | 4.875 | +.002 | 4.451 | ±.002 | 0.168 |

| GH1D-4875 | 4.875 | +.002 | 4.483 | ±.002 | 0.129 |

| GH3A-5000 | 5.000 | +.002 | 4.384 | ±.003 | 0.249 |

| GH2A-5000 | 5.000 | +.002 | 4.576 | ±.002 | 0.168 |

| GH1D-5000 | 5.000 | +.003 | 4.608 | ±.002 | 0.129 |

| GH3A-5125 | 5.125 | +.002 | 4.509 | ±.003 | 0.249 |

| GH2A-5125 | 5.125 | +.002 | 4.701 | ±.002 | 0.168 |

| GH1D-5125 | 5.125 | +.003 | 4.733 | ±.002 | 0.129 |

| GH4A-5250 | 5.250 | +.002 | 4.420 | ±.004 | 0.322 |

| GH3A-5250 | 5.250 | +.002 | 4.634 | ±.003 | 0.249 |

| GH2A-5250 | 5.250 | +.003 | 4.826 | ±.002 | 0.168 |

| GH1D-5250 | 5.250 | +.003 | 4.858 | ±.002 | 0.129 |

| GH4A-5375 | 5.375 | +.002 | 4.545 | ±.004 | 0.322 |

| GH3A-5375 | 5.375 | +.002 | 4.759 | ±.003 | 0.249 |

| GH2A-5375 | 5.375 | +.003 | 4.951 | ±.002 | 0.168 |

| GH1D-5375 | 5.375 | +.004 | 4.983 | ±.002 | 0.129 |

| GH4A-5500 | 5.500 | +.002 | 4.670 | ±.004 | 0.322 |

| GH3A-5500 | 5.500 | +.002 | 4.884 | ±.003 | 0.249 |

| GH2A-5500 | 5.500 | +.003 | 5.076 | ±.002 | 0.168 |

| GH1D-5500 | 5.500 | +.004 | 5.108 | ±.002 | 0.129 |

| GH4A-5625 | 5.625 | +.003 | 4.795 | ±.004 | 0.322 |

| GH3A-5625 | 5.625 | +.003 | 5.009 | ±.003 | 0.249 |

| GH2D-5625 | 5.625 | +.004 | 5.107 | ±.004 | 0.159 |

| GH4A-5750 | 5.750 | +.003 | 4.920 | ±.004 | 0.322 |

| GH3A-5750 | 5.750 | +.003 | 5.134 | ±.003 | 0.249 |

| GH2D-5750 | 5.750 | +.004 | 5.232 | ±.004 | 0.159 |

| GH4A-5875 | 5.875 | +.003 | 5.045 | ±.004 | 0.322 |

| GH3A-5875 | 5.875 | +.003 | 5.259 | ±.003 | 0.249 |

| GH2D-5875 | 5.875 | +.004 | 5.357 | ±.004 | 0.159 |

| GH4A-6000 | 6.000 | +.003 | 5.170 | ±.004 | 0.322 |

| GH3A-6000 | 6.000 | +.003 | 5.384 | ±.003 | 0.249 |

| GH2D-6000 | 6.000 | +.004 | 5.482 | ±.004 | 0.159 |

| GH4A-6125 | 6.125 | +.003 | 5.295 | ±.004 | 0.322 |

| GH3A-6125 | 6.125 | +.003 | 5.509 | ±.003 | 0.249 |

| GH2D-6125 | 6.125 | +.004 | 5.607 | ±.004 | 0.159 |

| GH4A-6250 | 6.250 | +.003 | 5.420 | ±.004 | 0.322 |

| GH3A-6250 | 6.250 | +.003 | 5.634 | ±.003 | 0.249 |

| GH2D-6250 | 6.250 | +.004 | 5.732 | ±.004 | 0.159 |

| GH4A-6375 | 6.375 | +.003 | 5.545 | ±.004 | 0.322 |

| GH3A-6375 | 6.375 | +.003 | 5.759 | ±.003 | 0.249 |

| GH2D-6375 | 6.375 | +.004 | 5.857 | ±.004 | 0.159 |

| GH4A-6500 | 6.500 | +.003 | 5.670 | ±.004 | 0.322 |

| GH3A-6500 | 6.500 | +.003 | 5.884 | ±.003 | 0.249 |

| GH2D-6500 | 6.500 | +.004 | 5.982 | ±.004 | 0.159 |

| GH4A-6750 | 6.750 | +.003 | 5.920 | ±.004 | 0.322 |

| GH3A-6750 | 6.750 | +.003 | 6.134 | ±.003 | 0.249 |

| GH2D-6750 | 6.750 | +.004 | 6.232 | ±.004 | 0.159 |

| GH4A-7000 | 7.000 | +.003 | 6.170 | ±.004 | 0.322 |

| GH3A-7000- | 7.000 | +.003 | 6.384 | ±.003 | 0.249 |

| GH2D-7000 | 7.000 | +.004 | 6.482 | ±.004 | 0.159 |

| GH4A-7250 | 7.250 | +.003 | 6.420 | ±.004 | 0.322 |

| GH3A-7250 | 7.250 | +.003 | 6.634 | ±.003 | 0.249 |

| GH2D-7250 | 7.250 | +.004 | 6.732 | ±.004 | 0.159 |

| GH4A-7500 | 7.500 | +.003 | 6.670 | ±.004 | 0.322 |

| GH3A-7500 | 7.500 | +.003 | 6.884 | ±.003 | 0.249 |

| GH2D-7500 | 7.500 | +.004 | 6.982 | ±.004 | 0.159 |

| GH4A-7750 | 7.750 | +.003 | 6.920 | ±.004 | 0.322 |

| GH3A-7750 | 7.750 | +.003 | 7.134 | ±.003 | 0.249 |

| GH2D-7750 | 7.750 | +.004 | 7.232 | ±.004 | 0.159 |

| GH4A-8000 | 8.000 | +.003 | 7.170 | ±.004 | 0.322 |

| GH3A-8000 | 8.000 | +.003 | 7.384 | ±.003 | 0.249 |

| GH2D-8000 | 8.000 | +.004 | 7.482 | ±.004 | 0.159 |

| GH4A-8250 | 8.250 | +.003 | 7.420 | ±.004 | 0.322 |

| GH3A-8250 | 8.250 | +.003 | 7.634 | ±.003 | 0.249 |

| GH2D-8250 | 8.250 | +.004 | 7.732 | ±.004 | 0.159 |

| GH4A-8500 | 8.500 | +.003 | 7.670 | ±.004 | 0.322 |

| GH3A-8500 | 8.500 | +.003 | 7.884 | ±.004 | 0.249 |

| GH2D-8500 | 8.500 | +.004 | 7.982 | ±.004 | 0.159 |

| GH4A-8750 | 8.750 | +.004 | 7.920 | ±.004 | 0.322 |

| GH4A-9000 | 9.000 | +.003 | 8.170 | ±.004 | 0.322 |

| GH3A-9000 | 9.000 | +.003 | 8.384 | ±.003 | 0.249 |

| GH2D-9000 | 9.000 | +.004 | 8.482 | ±.004 | 0.159 |

| GH4A-9500 | 9.500 | +.003 | 8.670 | ±.004 | 0.322 |

| GH3A-9500 | 9.500 | +.003 | 8.884 | ±.003 | 0.249 |

| GH2D-9500 | 9.500 | +.004 | 8.982 | ±.004 | 0.159 |

| GH4A-9750 | 9.750 | +.004 | 8.920 | ±.004 | 0.322 |

| GH4A-10000 | 10.000 | +.003 | 9.170 | ±.004 | 0.322 |

| GH3A-10000 | 10.000 | +.003 | 9.384 | ±.003 | 0.249 |

| GH2D-10000 | 10.000 | +.004 | 9.482 | ±.004 | 0.159 |

| GH4A-10500 | 10.500 | +.003 | 9.670 | ±.004 | 0.322 |

| GH3A-10500 | 10.500 | +.003 | 9.884 | ±.003 | 0.249 |

| GH2D-10500 | 10.500 | +.004 | 9.982 | ±.004 | 0.159 |

| GH4A-11000 | 11.000 | +.003 | 10.170 | ±.004 | 0.322 |

| GH3A-11000 | 11.000 | +.003 | 10.384 | ±.003 | 0.249 |

| GH2D-11000 | 11.000 | +.004 | 10.482 | ±.004 | 0.159 |

| GH4A-11500 | 11.500 | +.003 | 10.670 | ±.004 | 0.322 |

| GH3A-11500 | 11.500 | +.003 | 10.884 | ±.003 | 0.249 |

| GH2D-11500 | 11.500 | +.004 | 10.982 | ±.004 | 0.159 |

| GH4A-12000 | 12.000 | +.003 | 11.170 | ±.004 | 0.322 |

| GH3A-12000 | 12.000 | +.003 | 11.384 | ±.003 | 0.249 |

| GH2D-12000 | 12.000 | +.004 | 11.482 | ±.004 | 0.159 |

| GH4A-12500 | 12.500 | +.004 | 11.670 | ±.004 | 0.322 |

| GH4A-13000 | 13.000 | +.004 | 12.170 | ±.004 | 0.322 |

| GH4A-13500 | 13.500 | +.004 | 12.670 | ±.004 | 0.322 |

| GH4A-14000 | 14.000 | +.004 | 13.170 | ±.004 | 0.322 |

| GH4A-14500 | 14.500 | +.004 | 13.670 | ±.004 | 0.322 |

| GH4A-15000 | 15.000 | +.004 | 14.170 | ±.004 | 0.322 |

| GH4A-15500 | 15.500 | +.004 | 14.6780 | ±.004 | 0.322 |

| GH4A-16000 | 16.000 | +.003 | 15.170 | ±.004 | 0.322 |

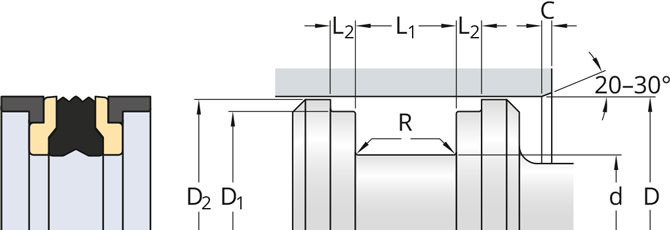

MD-L profiles have a nitrile rubber sealing element with polyester thermoplastic elastomer anti-extrusion rings, which incorporate polyacetal guide rings. The sealing element serves as a slide ring and also seals statically against the seal groove. The anti-extrusion rings support and protect the sealing element against gap extrusion. Both the guide and anti-extrusion rings are split to ease installation. MD-L profiles are suitable for pressures for pressures up to 250 bar (3,625 psi) and are available in metric and imperial sizes. Some metric sizes fit seal housings in accordance to ISO 6547.

Material: NBR/POM/TPC

| Part No | (D) ±H9 | (d) ±h9 | (L₁) +0.1/+0.35 | (L₂) +0.2 | (D₁) ±h9 | (D₂) ±h11 | (R) max | (C) min |

|---|---|---|---|---|---|---|---|---|

| 25*15*12.4 MD-L | 25.0 | 15.0 | 12.4 | 4.0 | 21.0 | 23.0 | 0.4 | 2.5 |

| 25*16*13.5 MD-L | 25.0 | 16.0 | 13.5 | 2.1 | 22.0 | 24.0 | 0.4 | 2.5 |

| 30*21*13.5 MD-L | 30.0 | 21.0 | 13.5 | 2.1 | 27.0 | 29.0 | 0.4 | 2.5 |

| 32*22*12.5 MD-L | 32.0 | 22.0 | 12.5 | 4.0 | 29.0 | 31.0 | 0.4 | 2.5 |

| 32*22*15.5 MD-L | 32.0 | 22.0 | 15.5 | 2.6 | 28.0 | 31.0 | 0.4 | 2.5 |

| 32*22*16.4 MD-L | 32.0 | 22.0 | 16.4 | 6.35 | 28.5 | 30.5 | 0.4 | 2.5 |

| 32*24*10 MD-L | 32.0 | 24.0 | 10.0 | 4.0 | 29.0 | 31.0 | 0.4 | 2.0 |

| 32*24*15.5 MD-L | 32.0 | 24.0 | 15.5 | 3.2 | 28.0 | 31.4 | 0.4 | 2.0 |

| 35*25*15.5 MD-L | 35.0 | 25.0 | 15.5 | 2.6 | 31.0 | 34.0 | 0.4 | 2.5 |

| 35*25*16.4 MD-L | 35.0 | 25.0 | 16.4 | 6.4 | 31.4 | 33.5 | 0.4 | 2.5 |

| 40*24*18.4 MD-L | 40.0 | 24.0 | 18.4 | 6.4 | 35.4 | 38.7 | 0.4 | 4.0 |

| 40*26*15.5 MD-L | 40.0 | 26.0 | 15.5 | 2.6 | 36.0 | 39.0 | 0.4 | 4.0 |

| 40*30*12.4 MD-L | 40.0 | 30.0 | 12.4 | 4.0 | 36.0 | 38.0 | 0.4 | 2.5 |

| 40*30*12.5 MD-L | 40.0 | 30.0 | 12.5 | 4.0 | 37.0 | 39.0 | 0.4 | 2.5 |

| 40*30*16.4 MD-L | 40.0 | 30.0 | 16.4 | 6.4 | 35.4 | 38.7 | 0.4 | 2.5 |

| 40*32*10 MD-L | 40.0 | 32.0 | 10.0 | 4.0 | 37.0 | 39.0 | 0.4 | 2.0 |

| 40*32*15.5 MD-L | 40.0 | 32.0 | 15.5 | 3.2 | 36.0 | 39.4 | 0.4 | 2.0 |

| 45*29*18.4 MD-L | 45.0 | 29.0 | 18.4 | 6.4 | 40.4 | 43.7 | 0.4 | 4.0 |

| 45*31*15.5 MD-L | 45.0 | 31.0 | 15.5 | 2.6 | 41.0 | 44.0 | 0.4 | 4.0 |

| 45*37*15.5 MD-L | 45.0 | 37.0 | 15.5 | 3.2 | 41.0 | 43.5 | 0.4 | 2.0 |

| 45*35*16.4 MD-L | 45.0 | 35.0 | 16.4 | 6.35 | 40.4 | 43.5 | 0.4 | 2.5 |

| 50*34*18.4 MD-L | 50.0 | 34.0 | 18.4 | 6.4 | 45.4 | 48.7 | 0.4 | 4.0 |

| 50*34*20.5 MD-L | 50.0 | 34.0 | 20.5 | 3.1 | 46.0 | 49.0 | 0.4 | 5.0 |

| 50*35*20 MD-L | 50.0 | 35.0 | 20.0 | 5.0 | 46.0 | 48.5 | 0.4 | 4.0 |

| 50*38*20.5 MD-L | 50.0 | 38.0 | 20.5 | 4.2 | 46.0 | 49.4 | 0.4 | 3.0 |

| 50*40*12.5 MD-L | 50.0 | 40.0 | 12.5 | 4.0 | 47.0 | 49.0 | 0.4 | 2.5 |

| 55*39*18.4 MD-L | 55.0 | 39.0 | 18.4 | 6.4 | 50.4 | 53.7 | 0.4 | 4.0 |

| 55*39*20.5 MD-L | 55.0 | 39.0 | 20.5 | 3.1 | 51.0 | 54.0 | 0.4 | 4.0 |

| 55*45*12.5 MD-L | 55.0 | 45.0 | 12.5 | 4.0 | 52.0 | 54.0 | 0.4 | 2.5 |

| 60*44*18.4 MD-L | 60.0 | 44.0 | 18.4 | 6.4 | 55.4 | 58.7 | 0.4 | 4.0 |

| 60*44*20.5 MD-L | 60.0 | 44.0 | 20.5 | 3.1 | 56.0 | 59.0 | 0.4 | 5.0 |

| 60*48*20.5 MD-L | 60.0 | 48.0 | 20.5 | 4.2 | 56.0 | 59.40 | 0.4 | 3.0 |

| 63*47*18.4 MD-L | 63.0 | 47.0 | 18.4 | 6.4 | 58.4 | 61.5 | 0.4 | 4.0 |

| 63*47*19.4 MD-L | 63.0 | 47.0 | 19.4 | 6.4 | 58.4 | 61.7 | 0.4 | 4.0 |

| 63*47*20.5 MD-L | 63.0 | 47.0 | 20.5 | 3.1 | 59.0 | 62.0 | 0.4 | 4.0 |

| 63*48*20 MD-L | 63.0 | 48.0 | 20.0 | 5.0 | 59.0 | 61.5 | 0.4 | 4.0 |

| 63*51*20.5 MD-L | 63.0 | 51.0 | 20.5 | 4.2 | 59.0 | 62.4 | 0.4 | 3.0 |

| 63*53*12.5 MD-L | 63.0 | 53.0 | 12.5 | 4.0 | 60.0 | 62.0 | 0.4 | 2.5 |

| 65*49*20.5 MD-L | 65.0 | 49.0 | 20.5 | 3.1 | 60.4 | 53.7 | 0.4 | 4.0 |

| 65*50*18.4 MD-L | 65.0 | 50.0 | 18.4 | 6.4 | 60.4 | 63.5 | 0.4 | 4.0 |

| 70*50*22.4 MD-L | 70.0 | 50.0 | 22.4 | 6.4 | 64.2 | 68.3 | 0.8 | 5.0 |

| 70*54*20.5 MD-L | 70.0 | 54.0 | 20.5 | 3.1 | 66.0 | 69.0 | 0.4 | 4.0 |

| 70*55*20 MD-L | 70.0 | 55.0 | 20.0 | 5.0 | 66.0 | 68.5 | 0.4 | 4.0 |

| 70*58*20.5 MD-L | 70.0 | 58.0 | 20.5 | 4.2 | 66.0 | 69.4 | 0.4 | 3.0 |

| 75*55*22.4 MD-L | 75.0 | 55.0 | 22.4 | 6.4 | 69.2 | 73.3 | 0.8 | 5.0 |

| 75*59*20.5 MD-L | 75.0 | 59.0 | 20.5 | 3.1 | 71.0 | 74.0 | 0.4 | 3.0 |

| 80*60*22.4 MD-L | 80.0 | 60.0 | 22.4 | 6.4 | 74.2 | 78.3 | 0.8 | 5.0 |

| 80*60*25 MD-L | 80.0 | 60.0 | 25.0 | 6.3 | 75.0 | 78.0 | 0.8 | 5.0 |

| 80*62*22.5 MD-L | 80.0 | 62.0 | 22.5 | 3.6 | 76.0 | 79.0 | 0.4 | 4.5 |

| 80*65*20 MD-L | 80.0 | 65.0 | 20.0 | 5.0 | 76.0 | 78.5 | 0.4 | 4.0 |

| 80*66*22.5 MD-L | 80.0 | 66.0 | 22.5 | 5.2 | 76.0 | 79.4 | 0.4 | 3.5 |

| 85*65*22.4 MD-L | 85.0 | 65.0 | 22.4 | 6.4 | 79.2 | 83.3 | 0.8 | 5.0 |

| 90*70*22.4 MD-L | 90.0 | 70.0 | 22.4 | 6.4 | 84.2 | 88.3 | 0.8 | 5.0 |

| 90*72*22.5 MD-L | 90.0 | 72.0 | 22.5 | 3.6 | 86.0 | 89.0 | 0.4 | 4.5 |

| 90*75*20 MD-L | 90.0 | 75.0 | 20.0 | 5.0 | 86.0 | 88.5 | 0.4 | 4.0 |

| 95*75*22.4 MD-L | 95.0 | 75.0 | 22.4 | 6.4 | 89.0 | 93.3 | 0.8 | 5.0 |

| 100*75*22.4 MD-L | 100.0 | 75.0 | 22.4 | 6.4 | 93.2 | 98.0 | 0.8 | 6.5 |

| 100*80*25 MD-L | 100.0 | 80.0 | 25.0 | 6.3 | 95.0 | 98.0 | 0.8 | 5.0 |

| 100*82*22.5 MD-L | 100.0 | 82.0 | 22.5 | 3.6 | 96.0 | 99.0 | 0.8 | 5.0 |

| 100-85*20 MD-L | 100.0 | 85.0 | 20.0 | 5.0 | 96.0 | 98.5 | 0.4 | 4.0 |

| 100*86*22.5 MD-L | 100.0 | 86.0 | 22.5 | 5.2 | 96.0 | 99.4 | 0.4 | 3.5 |

| 105*92.5*14 MD-L | 105.0 | 92.5 | 14.0 | 5.2 | 99.0 | 103.5 | 0.4 | 3.5 |

| 110*85*22.4 MD-L | 110.0 | 85.0 | 22.4 | 6.4 | 103.1 | 108.0 | 0.8 | 6.5 |

| 110*85*25.4 MD-L | 110.0 | 85.0 | 25.4 | 6.4 | 103.1 | 108.0 | 0.8 | 6.5 |

| 110*92*22.5 MD-L | 110.0 | 92.0 | 22.5 | 3.6 | 106.0 | 109.0 | 0.8 | 5.0 |

| 110*95*20 MD-L | 110.0 | 95.0 | 20.0 | 5.0 | 106.0 | 108.5 | 0.4 | 4.0 |

| 110*96*22.5 MD-L | 110.0 | 96.0 | 22.5 | 5.2 | 106.0 | 109.4 | 0.4 | 3.5 |

| 115*90*22.4 MD-L | 115.0 | 90.0 | 22.4 | 6.4 | 108.1 | 113.0 | 0.8 | 6.5 |

| 120*95*22.4 MD-L | 120.0 | 95.0 | 22.4 | 6.4 | 113.1 | 118.0 | 0.8 | 6.5 |

| 125*100*25.4 MD-L | 125.0 | 100.0 | 25.4 | 6.4 | 118.1 | 123.0 | 0.8 | 6.5 |

| 125*100*32 MD-L | 125.0 | 100.0 | 32.0 | 10.0 | 119.0 | 123.0 | 0.8 | 6.5 |

| 125*103*26.5 MD-L | 125.0 | 103.0 | 26.5 | 5.1 | 121.0 | 124.0 | 0.8 | 5.0 |

| 125*105*25 MD-L | 125.0 | 105.0 | 25.0 | 6.3 | 120.0 | 123.0 | 0.8 | 5.0 |

| 125*105*25.4 MD-L | 125.0 | 105.0 | 25.4 | 6.4 | 119.1 | 123.3 | 0.8 | 5.0 |

| 125*108*26.5 MD-L | 125.0 | 108.0 | 26.5 | 7.2 | 121.0 | 124.4 | 0.4 | 4.5 |

| 130*105*25.4 MD-L | 130.0 | 105.0 | 25.4 | 6.4 | 123.1 | 128.0 | 0.8 | 6.5 |

| 140*115*25.4 MD-L | 140.0 | 115.0 | 25.4 | 6.4 | 133.0 | 138.0 | 0.8 | 6.5 |

| 140*120*25 MD-L | 140.0 | 120.0 | 25.0 | 6.3 | 135.0 | 138.0 | 0.8 | 5.0 |

| 145*120*25.4 MD-L | 145.0 | 120.0 | 25.4 | 6.4 | 138.3 | 143.0 | 0.8 | 6.5 |

| 150*125*25.4 MD-L | 150.0 | 125.0 | 25.4 | 6.4 | 143.0 | 148.0 | 0.8 | 6.5 |

| 160*130*25.4 MD-L | 160.0 | 130.0 | 25.4 | 6.4 | 153.0 | 157.9 | 0.8 | 7.5 |

| 160*135*25.4*9.5 MD-L | 160.0 | 135.0 | 25.4 | 9.5 | 152.6 | 157.5 | 0.8 | 6.5 |

| 160*138*26.5 MD-L | 160.0 | 138.0 | 26.5 | 5.1 | 156.0 | 159.0 | 0.8 | 5.0 |

| 160*140*25 MD-L | 160.0 | 140.0 | 25.0 | 6.3 | 155.0 | 158.0 | 0.8 | 5.0 |

| 160*143*26.5 MD-L | 160.0 | 143.0 | 26.5 | 7.2 | 156.0 | 159.4 | 0.8 | 5.0 |

| 170*145*25.4*12.7 MD-L | 170.0 | 145.0 | 25.4 | 12.7 | 161.7 | 167.1 | 0.8 | 6.5 |

| 180*150*35.4 MD-L | 180.0 | 150.0 | 35.4 | 6.4 | 173.0 | 178.0 | 0.8 | 7.5 |

| 180*155*25.4*12.7 MD-L | 180.0 | 155.0 | 25.4 | 12.7 | 171.7 | 177.7 | 0.8 | 6.5 |

| 190*165*25.4 MD-L | 190.0 | 165.0 | 25.4 | 12.7 | 181.7 | 188.0 | 0.8 | 6.5 |

| 200*170*35.4 MD-L | 200.0 | 170.0 | 35.4 | 6.4 | 193.0 | 198.0 | 0.8 | 7.5 |

| 200*170*36 MD-L | 200.0 | 170.0 | 36.0 | 12.5 | 192.0 | 197.0 | 0.8 | 7.5 |

| 200*175*25.4-12.7 MD-L | 200.0 | 175.0 | 25.4 | 12.7 | 191.6 | 197.0 | 0.8 | 6.5 |

| 200*180*31.5 MD-L | 200.0 | 180.0 | 31.5 | 9.2 | 196.0 | 199.4 | 0.8 | 5.0 |

| 220*190*35.4 MD-L | 220.0 | 190.0 | 35.4 | 6.4 | 213.0 | 218.0 | 0.8 | 7.5 |

| 220*195-25.4-12.7 MD-L | 220.0 | 195.0 | 25.4 | 12.7 | 211.6 | 217.0 | 0.8 | 6.5 |

| 250*220*35.4 MD-L | 250.0 | 220.0 | 35.4 | 6.4 | 243.0 | 248.0 | 0.8 | 7.5 |

| 250*225*25.4 MD-L | 250.0 | 225.0 | 25.4 | 12.7 | 241.6 | 247.0 | 0.8 | 6.5 |

| Part No | (D) ±H9 | (d) ±h9 | (L₁) +.007 | (L₂) +.003 | (D₁) ±h9 | (D₂) ±h11 | (R) max | (C) min |

|---|---|---|---|---|---|---|---|---|

| 1.500*1.000*0.625*0.250 MD-L | 1.500 | 1.000 | 0.625 | 0.250 | 1.360 | 1.458 | 0.008 | 0.125 |

| 1.750*1.125*0.750*0.250 MD-L | 1.750 | 1.125 | 0.750 | 0.250 | 1.570 | 1.698 | 0.008 | 0.156 |

| 2.000*1.375*0.750*0.250 MD-L | 2.000 | 1.375 | 0.750 | 0.250 | 1.820 | 1.948 | 0.008 | 0.156 |

| 2.250*1.625*0.750*0.250 MD-L | 2.250 | 1.625 | 0.750 | 0.250 | 2.069 | 2.197 | 0.008 | 0.156 |

| 2.375*1.750*0.750*0.250 MD-L | 2.375 | 1.750 | 0.750 | 0.250 | 2.194 | 2.322 | 0.008 | 0.156 |

| 2.500*1.875*0.750*0.250 MD-L | 2.500 | 1.875 | 0.750 | 0.250 | 2.319 | 2.446 | 0.008 | 0.156 |

| 2.750*2.000*0.937*0.250 MD-L | 2.750 | 2.000 | 0.937 | 0.250 | 2.522 | 2.685 | 0.008 | 0.187 |

| 3.000*2.250*0.937*0.250 MD-L | 3.000 | 2.250 | 0.937 | 0.250 | 2.772 | 2.935 | 0.008 | 0.187 |

| 3.250*2.500*0.937*0.250 MD-L | 3.250 | 2.500 | 0.937 | 0.250 | 3.021 | 3.184 | 0.008 | 0.187 |

| 3.500*2.750*0.937*0.250 MD-L | 3.500 | 2.750 | 0.937 | 0.250 | 3.271 | 3.434 | 0.008 | 0.187 |

| 4.000*3.250*0.937*0.250 MD-L | 4.000 | 3.250 | 0.937 | 0.250 | 3.770 | 3.933 | 0.008 | 0.187 |

| 5.000*4.000*1.250*0.250 MD-L | 5.000 | 4.000 | 1.250 | 0.250 | 4.728 | 4.921 | 0.015 | 0.218 |

| 5.500*4.500*1.250*0.375 MD-L | 5.500 | 4.500 | 1.250 | 0.375 | 5.213 | 5.410 | 0.015 | 0.218 |

| 6.000*5.000*0.250*0.375 MD-L | 6.000 | 5.000 | 1.250 | 0.375 | 5.709 | 5.902 | 0.015 | 0.218 |

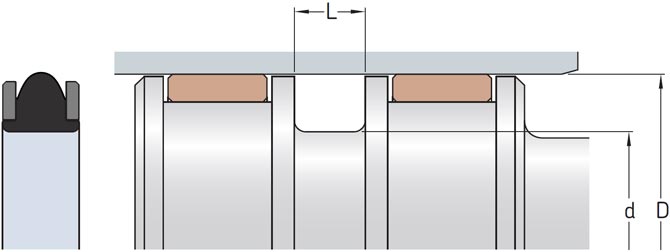

Designed to fit imperial o’ring housings in accordance to ISO3601 (BS1806/AS568A o’ring sizing), T-seals are an ideal replacement for o’rings. The T-shaped sealing element serves as a slide ring that’s highly resistant twisting and spiral failure. Piston T-seals seal statically against the groove ID and are suitable for pressures up to 345 bar (5,000 psi).

MPT profiles have a nitrile (NBR) rubber sealing element and hard polyamide, non-locking anti-extrusion rings.

| Part No | Nom | (d) | (D) | (L) | O’ring Ref |

|---|---|---|---|---|---|

| MPT-001 | 3/8*3/16*3/32 | 0.198 | 0.374 | 0.140 | BS106 |

| MPT-002 | 7/16*1/4*3/32 | 0.261 | 0.437 | 0.140 | BS108 |

| MPT-003 | 1/2*5/16*3/32 | 0.323 | 0.499 | 0.140 | BS109 |

| MPT-004 | 9/16*5/16*1/8 | 0.320 | 0.562 | 0.187 | BS203 |

| MPT-005 | 5/8*3/8*1/8 | 0.383 | 0.625 | 0.187 | BS204 |

| MPT-006 | 11/16*7/16*1/8 | 0.445 | 0.687 | 0.187 | BS205 |

| MPT-007 | 3/4*1/2*1/8 | 0.505 | 0.750 | 0.187 | BS206 |

| MPT-008 | 13/16*9/16*1/8 | 0.570 | 0.812 | 0.187 | BS207 |

| MPT-009 | 7/8*5/8*1/8 | 0.630 | 0.875 | 0.187 | BS208 |

| MPT-010 | 15/16*11/16*1/8 | 0.695 | 0.937 | 0.187 | BS209 |

| MPT-011 | 1*3/4*1/8 | 0.756 | 1.001 | 0.187 | BS210 |

| MPT-012 | 1-1/16*13/16*1/8 | 0.818 | 1.063 | 0.187 | BS211 |

| MPT-013 | 1-1/8*7/8*1/8 | 0.881 | 1.126 | 0.187 | BS212 |

| MPT-014 | 1-3/16*15/16*1/8 | 0.943 | 1.188 | 0.187 | BS213 |

| MPT-015 | 1-1/4*1*1/8 | 1.006 | 1.251 | 0.187 | BS214 |

| MPT-016 | 1-5/16*1-1/16*1/8 | 1.068 | 1.313 | 0.187 | BS215 |

| MPT-017 | 1-3/8*1-1/8*1/8 | 1.131 | 1.376 | 0.187 | BS216 |

| MPT-018 | 1-7/16*1-3/16*1/8 | 1.193 | 1.438 | 0.187 | BS217 |

| MPT-019 | 1-1/2*1-1/4*1/8 | 1.256 | 1.501 | 0.187 | BS218 |

| MPT-020 | 1-9/16*1-5/16*1/8 | 1.320 | 1.562 | 0.187 | BS219 |

| MPT-021 | 1-5/8*1-3/8 *1/8 | 1.381 | 1.626 | 0.187 | BS220 |

| MPT-022 | 1-3/4*1-1/2*1/8 | 1.506 | 1.751 | 0.187 | BS222 |

| MPT-023 | 1-7/8*1-1/2*3/16 | 1.502 | 1.876 | 0.281 | BS325 |

| MPT-024 | 2*1-5/8*3/16 | 1.627 | 2.001 | 0.281 | BS326 |

| MPT-025 | 2-1/8*1-3/4*3/16 | 1.752 | 2.126 | 0.281 | BS327 |

| MPT-026 | 2-1/4*1-7/8*3/16 | 1.877 | 2.251 | 0.281 | BS328 |

| MPT-027 | 2-3/8*2*3/16 | 2.002 | 2.376 | 0.281 | BS329 |

| MPT-028 | 2-1/2*2-1/8*3/16 | 2.127 | 2.501 | 0.281 | BS330 |

| MPT-029 | 2-5/8*2-1/4*3/16 | 2.252 | 2.626 | 0.281 | BS331 |

| MPT-030 | 2-3/4*2-3/8*3/16 | 2.377 | 2.751 | 0.281 | BS332 |

| MPT-031 | 2-7/8*2-1/2*3/16 | 2.502 | 2.876 | 0.281 | BS333 |

| MPT-032 | 3*2-5/8*3/16 | 2.627 | 3.001 | 0.281 | BS334 |

| MPT-033 | 3-1/8*2-3/4*3/16 | 2.752 | 3.126 | 0.281 | BS335 |

| MPT-034 | 3-1/4*2-7/8*3/16 | 2.877 | 3.251 | 0.281 | BS336 |

| MPT-035 | 3-1/2*3-1/8*3/16 | 3.128 | 3.502 | 0.281 | BS338 |

| MPT-036 | 3-5/8*3-1/4*3/16 | 3.253 | 3.627 | 0.281 | BS339 |

| MPT-037 | 3-3/4*3*3/8*3/16 | 3.378 | 3.752 | 0.281 | BS340 |

| MPT-038 | 3-7/8*3-1/2*3/16 | 3.503 | 3.877 | 0.281 | BS341 |

| MPT-039 | 4*3-5/8*3/16 | 3.628 | 4.002 | 0.281 | BS342 |

| MPT-040 | 4-1/8*3-3/4*3/16 | 3.753 | 4.127 | 0.281 | BS343 |

| MPT-041 | 4-1/4*3-7/8*3/16 | 3.878 | 4.252 | 0.281 | BS344 |

| MPT-042 | 4-3/8*4*3/16 | 4.003 | 4.377 | 0.281 | BS345 |

| MPT-043 | 4-1/2*4-1/8*3/16 | 4.128 | 4.502 | 0.281 | BS346 |

| MPT-044 | 4-5/8*4-1/4*3/16 | 4.253 | 4.627 | 0.281 | BS347 |

| MPT-045 | 4-3/4*4-3/8*3/16 | 4.378 | 4.752 | 0.281 | BS348 |

| MPT-046 | 4-7/8*4-1/2*3/16 | 4.503 | 4.877 | 0.281 | BS349 |

| MPT-047 | 5*4-5/8*3/16 | 4.629 | 5.003 | 0.281 | BS350 |

| MPT-048 | 5-1/8*4-5/8*1/4 | 4.649 | 5.128 | 0.375 | BS426 |

| MPT-049 | 5-1/4*4-3/4*1/4 | 4.774 | 5.253 | 0.375 | BS427 |

| MPT-050 | 5-3/8*4-7/8*1/4 | 4.903 | 5.377 | 0.375 | BS428 |

| MPT-051 | 5-1/2*5*1/4 | 5.024 | 5.503 | 0.375 | BS429 |

| MPT-052 | 5-5/8*5*1/8*1/4 | 5.153 | 5.627 | 0.375 | BS430 |

| MPT-053 | 5-3/4*5-1/4*1/4 | 5.274 | 5.753 | 0.375 | BS431 |

| MPT-054 | 5-7/8*5-3/8*1/4 | 5.399 | 5.878 | 0.375 | BS432 |

| MPT-055 | 6*5-1/2*1/4 | 5.524 | 6.003 | 0.375 | BS433 |

| MPT-056 | 6-1/8*5-5/8*1/4 | 5.629 | 6.128 | 0.375 | BS434 |

| MPT-057 | 6-1/4*5-3/4*1/4 | 5.774 | 6.253 | 0.375 | BS435 |

| MPT-058 | 6-1/2*6*1/4 | 6.024 | 6.503 | 0.375 | BS437 |

| MPT-059 | 6-3/4*6-1/4*1/4 | 6.278 | 6.752 | 0.375 | BS438 |

| MPT-060 | 7*6-1/2*1/4 | 6.524 | 7.003 | 0.375 | BS439 |

| MPT-061 | 7-1/4*6-3/4*1/4 | 6.774 | 7.253 | 0.375 | BS440 |

| MPT-062 | 7-1/2*7*1/4 | 7.024 | 7.503 | 0.375 | BS441 |

| MPT-063 | 7-3/4*7-1/4*1/4 | 7.278 | 7.752 | 0.375 | BS442 |

| MPT-064 | 8*7-1/2*1/4 | 7.524 | 8.003 | 0.375 | BS443 |

| MPT-065 | 8-1/4*7-3/4*1/4 | 7.774 | 8.253 | 0.375 | BS444 |

| MPT-066 | 8-1/2*8*1/4 | 8.024 | 8.503 | 0.375 | BS445 |

| MPT-067 | 9*8-1/2*1/4 | 8.524 | 9.003 | 0.375 | BS446 |

| MPT-068 | 9-1/2*9*1/4 | 9.024 | 9.503 | 0.375 | BS447 |

| MPT-069 | 10*9-1/2*1/4 | 9.524 | 10.003 | 0.375 | BS448 |

| MPT-070 | 10-1/2*10*1/4 | 10.024 | 10.503 | 0.375 | BS449 |

| MPT-071 | 11*10-1/2*1/4 | 10.524 | 11.003 | 0.375 | BS450 |

| MPT-072 | 11-1/2*11*1/4 | 11.024 | 11.503 | 0.375 | BS451 |

| MPT-073 | 12*11-1/2*1/4 | 11.524 | 12.003 | 0.375 | BS452 |

MPT profiles have a nitrile (NBR) rubber sealing element and hard polyamide anti-extrusion rings that lock into the rubber sealing element.

| Part No | Nom | (d) | (D) | (L) | O’ring Ref |

|---|---|---|---|---|---|

| LTP-204 | 5/8*3/8*1/8 | 0.383 | 0.625 | 0.187 | BS204 |

| LTP-206 | 11/16*7/16*1/8 | 0.508 | 0.750 | 0.187 | BS206 |

| LTP-208 | 7/8*5/8*1/8 | 0.633 | 0.875 | 0.187 | BS208 |

| LTP-209 | 15/16*11/16*1/8 | 0.695 | 0.937 | 0.187 | BS209 |

| LTP-210 | 1*3/4*1/8 | 0.758 | 1.000 | 0.187 | BS210 |

| LTP-211 | 1-1/16*13/16*1/8 | 0.820 | 1.062 | 0.187 | BS211 |

| LTP-212 | 1-1/8*7/8*1/8 | 0.883 | 1.125 | 0.187 | BS212 |

| LTP-214 | 1-1/4*1*1/8 | 1.008 | 1.250 | 0.187 | BS214 |

| LTP-216 | 1-3/8*1-1/8*1/8 | 1.133 | 1.375 | 0.187 | BS216 |

| LTP-218 | 1-1/2*1-1/4*1/8 | 1.258 | 1.500 | 0.187 | BS218 |

| LTP-220 | 1-5/8*1-3/8 *1/8 | 1.383 | 1.625 | 0.187 | BS220 |

| LTP-222 | 1-3/4*1-1/2*1/8 | 1.508 | 1.750 | 0.187 | BS222 |

| LTP-325 | 1-7/8*1-1/2*3/16 | 1.505 | 1.875 | 0.281 | BS325 |

| LTP-326 | 2*1-5/8*3/16 | 1.630 | 2.000 | 0.281 | BS326 |

| LTP-327 | 2-1/8*1-3/4*3/16 | 1.755 | 2.125 | 0.281 | BS327 |

| LTP-328 | 2-1/4*1-7/8*3/16 | 1.880 | 2.250 | 0.281 | BS328 |

| LTP-329 | 2-3/8*2*3/16 | 2.005 | 2.375 | 0.281 | BS329 |

| LTP-330 | 2-1/2*2-1/8*3/16 | 2.130 | 2.500 | 0.281 | BS330 |

| LTP-331 | 2-5/8*2-1/4*3/16 | 2.255 | 2.625 | 0.281 | BS331 |

| LTP-332 | 2-3/4*2-3/8*3/16 | 2.380 | 2.750 | 0.281 | BS332 |

| LTP-333 | 2-7/8*2-1/2*3/16 | 2.505 | 2.875 | 0.281 | BS333 |

| LTP-334 | 3*2-5/8*3/16 | 2.630 | 3.000 | 0.281 | BS334 |

| LTP-335 | 3-1/8*2-3/4*3/16 | 2.755 | 3.125 | 0.281 | BS335 |

| LTP-336 | 3-1/4*2-7/8*3/16 | 2.880 | 3.250 | 0.281 | BS336 |

| LTP-338 | 3-1/2*3-1/8*3/16 | 3.130 | 3.500 | 0.281 | BS338 |

| LTP-340 | 3-3/4*3*3/8*3/16 | 3.380 | 3.750 | 0.281 | BS340 |

| LTP-341 | 3-7/8*3-1/2*3/16 | 3.505 | 3.875 | 0.281 | BS341 |

| LTP-342 | 4*3-5/8*3/16 | 3.630 | 4.000 | 0.281 | BS342 |

| LTP-343 | 4-1/8*3-3/4*3/16 | 3.755 | 4.125 | 0.281 | BS343 |

| LTP-344 | 4-1/4*3-7/8*3/16 | 3.880 | 4.250 | 0.281 | BS344 |

| LTP-346 | 4-1/2*4-1/8*3/16 | 4.130 | 4.500 | 0.281 | BS346 |

| LTP-348 | 4-3/4*4-3/8*3/16 | 4.380 | 4.750 | 0.281 | BS348 |

| LTP-349 | 4-7/8*4-1/2*3/16 | 4.505 | 4.875 | 0.281 | BS349 |

| LTP-350 | 5*4-5/8*3/16 | 4.630 | 5.000 | 0.281 | BS350 |

| LTP-426 | 5-1/8*4-5/8*1/4 | 4.653 | 5.128 | 0.375 | BS426 |

| LTP-427 | 5-1/4*4-3/4*1/4 | 4.778 | 5.252 | 0.375 | BS427 |

| LTP-428 | 5-3/8*4-7/8*1/4 | 4.903 | 5.375 | 0.375 | BS428 |

| LTP-429 | 5-1/2*5*1/4 | 5.028 | 5.502 | 0.375 | BS429 |

| LTP-430 | 5-5/8*5*1/8*1/4 | 5.153 | 5.627 | 0.375 | BS430 |

| LTP-431 | 5-3/4*5-1/4*1/4 | 5.278 | 5.752 | 0.375 | BS431 |

| LTP-433 | 6*5-1/2*1/4 | 5.528 | 6.002 | 0.375 | BS433 |

| LTP-437 | 6-1/2*6*1/4 | 6.028 | 6.502 | 0.375 | BS437 |

| LTP-439 | 7*6-1/2*1/4 | 6.528 | 7.002 | 0.375 | BS439 |

| LTP-447 | 9-1/2*9*1/4 | 9.028 | 9.502 | 0.375 | BS447 |

| LTP-448 | 10*9-1/2*1/4 | 9.528 | 10.002 | 0.375 | BS448 |

| LTP-452 | 12*11-1/2*1/4 | 11.528 | 12.002 | 0.375 | BS452 |

| LTP1-334 | 3*2-5/8*0.334 | 2.630 | 3.000 | 0.311 | BS334 |

| LTP1-338 | 3-1/2*3-1/8*0.334 | 3.130 | 3.500 | 0.311 | BS338 |

| LTP1-439 | 7*6-1/2*0.475 | 6.528 | 7.002 | 0.408 | BS439 |

| LTP1-441 | 7-1/2*7*0.475 | 7.528 | 7.002 | 0.408 | BS441 |

| LTP1-452 | 12*11-1/2*0.475 | 11.528 | 11.502 | 0.408 | BS452 |

| LTP2-214 | 1-1/4*1*0.304 | 1.008 | 1.000 | 0.304 | BS214 |

| LTP2-218 | 1-1/2*1-1/4*0.304 | 1.258 | 1.500 | 0.304 | BS218 |

| LTP2-328 | 2-1/4*1-7/8*0.334 | 1.880 | 2.250 | 0.410 | BS328 |

| LTP2-330 | 2-1/2*2-1/8*0.334 | 2.130 | 2.500 | 0.410 | BS330 |

| LTP2-334 | 3*2-5/8*0.334 | 2.630 | 3.000 | 0.410 | BS334 |

| LTP2-338 | 3-1/2*3-1/8*0.334 | 3.130 | 3.500 | 0.410 | BS338 |

| LTP2-342 | 4*3-5/8*0.334 | 3.630 | 4.000 | 0.410 | BS342 |

| LTP2-350 | 5*4-5/8*0.334 | 4.630 | 5.000 | 0.410 | BS350 |

| LTP2-425 | 4-1/2*5*0.424 | 4.528 | 5.000 | 0.538 | BS425 |

| LTP2-433 | 6*5-1/2*0.424 | 5.528 | 6.002 | 0.538 | BS433 |

| LTP2-435 | 6-1/4*5-3/4*0.424 | 5.778 | 6.252 | 0.538 | BS435 |

| LTP2-444 | 8-1/4*7-3/4*0.424 | 7.778 | 8.252 | 0.538 | BS444 |

| LTP2-452 | 12*11-1/2*0.424 | 11.528 | 12.002 | 0.538 | BS452 |

HOURS OF OPERATION • AEST Monday to Thursday 8.30 am – 5.30 pm