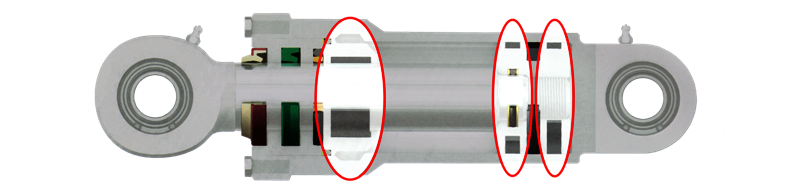

Wear rings and guide strips accommodate radial loads of forces acting on the cylinder assembly and guide the rod in the cylinder head as well as guide the piston in the cylinder bore.

Wear rings and guide strips accommodate radial loads of forces acting on the cylinder assembly and guide the rod in the cylinder head as well as guide the piston in the cylinder bore.

Guides are generally made of a polymer material which avoids metal-to-metal contact between moving parts in a working hydraulic cylinder. Compared to metal guides, polymer guides provide the following advantages in hydraulic cylinders.

The most common materials for wear guides are listed below.

Glass fibre reinforced polyamide (glass filled nylon) guides are suitable for medium to heavy duty applications and are characterised by the following properties:

Phenolic/fabric composite consists of cotton fabric bound with thermoset phenolic resin. Its structure and ability of the fabric fibres to absorb a certain amount of oil make phenolic guides almost self-lubricating. However, phenolic guides should not be used at high stroke speeds over 0.5m/s (1.6 ft/s). Phenolic wear rings are suitable for medium to heavy duty applications and are characterised by the following properties:

PTFE is typically used in wear rings where low friction and resistance to chemicals, heat and wear are essential. However, PTFE should only be used in applications with low surface pressure. To obtain optimal wear resistance, PTFE materials are available with different fillers such as bronze and carbon powder. PTFE wear rings are characterised by the following properties:

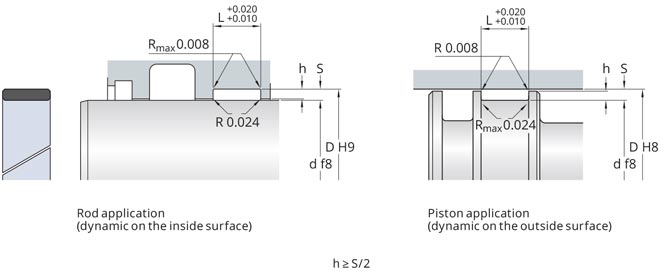

These standard guide rings can be used in piston and rod applications. WR imperial wear rings are made of glass fibre reinforced polyamide as standard. Non-standard wear ring materials can be made to order.

Material: Glass Filled Nylon

| Part No | (D) ±H8/H9 | (d) f8 | (L) +.020/+.010 | (S) |

|---|---|---|---|---|

| WR125-1250-250 | 1.250 | 1.000 | 0.250 | 0.125 |

| WR125-1250-375 | 1.250 | 1.000 | 0.375 | 0.125 |

| WR125-1250-500 | 1.250 | 1.000 | 0.500 | 0.125 |

| WR125-1500-250 | 1.500 | 1.250 | 0.250 | 0.125 |

| WR125-1500-375 | 1.500 | 1.250 | 0.375 | 0.125 |

| WR125-1500-500 | 1.500 | 1.250 | 0.500 | 0.125 |

| WR125-1500-625 | 1.500 | 1.250 | 0.625 | 0.125 |

| WR125-1500-750 | 1.500 | 1.250 | 0.750 | 0.125 |

| WR125-1625-375 | 1.625 | 1.375 | 0.375 | 0.125 |

| WR125-1625-500 | 1.625 | 1.375 | 0.500 | 0.125 |

| WR125-1750-250 | 1.750 | 1.500 | 0.250 | 0.125 |

| WR125-1750-375 | 1.750 | 1.500 | 0.375 | 0.125 |

| WR125-1750-500 | 1.750 | 1.500 | 0.500 | 0.125 |

| WR125-1750-750 | 1.750 | 1.500 | 0.750 | 0.125 |

| WR125-1750-1000 | 1.750 | 1.500 | 1.000 | 0.125 |

| WR125-1875-375 | 1.875 | 1.625 | 0.375 | 0.125 |

| WR125-1875-500 | 1.875 | 1.625 | 0.500 | 0.125 |

| WR125-2000-250 | 2.000 | 1.750 | 0.250 | 0.125 |

| WR125-2000-375 | 2.000 | 1.750 | 0.375 | 0.125 |

| WR125-2000-500 | 2.000 | 1.750 | 0.500 | 0.125 |

| WR125-2000-625 | 2.000 | 1.750 | 0.625 | 0.125 |

| WR125-2000-750 | 2.000 | 1.750 | 0.750 | 0.125 |

| WR125-2000-1000 | 2.000 | 1.750 | 1.000 | 0.125 |

| WR125-2000-1250 | 2.000 | 1.750 | 1.250 | 0.125 |

| WR125-2000-1500 | 2.000 | 1.750 | 1.500 | 0.125 |

| WR125-2125-750 | 2.125 | 1.875 | 0.750 | 0.125 |

| WR125-2250-250 | 2.250 | 2.000 | 0.250 | 0.125 |

| WR125-2250-375 | 2.250 | 2.000 | 0.375 | 0.125 |

| WR125-2250-500 | 2.250 | 2.000 | 0.500 | 0.125 |

| WR125-2250-625 | 2.250 | 2.000 | 0.625 | 0.125 |

| WR125-2250-750 | 2.250 | 2.000 | 0.750 | 0.125 |

| WR125-2250-1000 | 2.250 | 2.000 | 1.000 | 0.125 |

| WR125-2250-1250 | 2.250 | 2.000 | 1.250 | 0.125 |

| WR125-2250-1500 | 2.250 | 2.000 | 1.500 | 0.125 |

| WR125-2375-750 | 2.375 | 2.125 | 0.750 | 0.125 |

| WR125-2500-187 | 2.500 | 2.250 | 0.187 | 0.125 |

| WR125-2500-250 | 2.500 | 2.250 | 0.250 | 0.125 |

| WR125-2500-312 | 2.500 | 2.250 | 0.312 | 0.125 |

| WR125-2500-375 | 2.500 | 2.250 | 0.375 | 0.125 |

| WR125-2500-500 | 2.500 | 2.250 | 0.500 | 0.125 |

| WR125-2500-625 | 2.500 | 2.250 | 0.625 | 0.125 |

| WR125-2500-750 | 2.500 | 2.250 | 0.750 | 0.125 |

| WR125-2500-875 | 2.500 | 2.250 | 0.875 | 0.125 |

| WR125-2500-1000 | 2.500 | 2.250 | 1.000 | 0.125 |

| WR125-2500-1250 | 2.500 | 2.250 | 1.250 | 0.125 |

| WR125-2625-500 | 2.625 | 2.375 | 0.500 | 0.125 |

| WR125-2625-750 | 2.625 | 2.375 | 0.750 | 0.125 |

| WR125-2750-250 | 2.750 | 2.500 | 0.250 | 0.125 |

| WR125-2750-375 | 2.750 | 2.500 | 0.375 | 0.125 |

| WR125-2750-500 | 2.750 | 2.500 | 0.500 | 0.125 |

| WR125-2750-625 | 2.750 | 2.500 | 0.625 | 0.125 |

| WR125-2750-750 | 2.750 | 2.500 | 0.750 | 0.125 |

| WR125-2750-1000 | 2.750 | 2.500 | 1.000 | 0.125 |

| WR125-2750-1250 | 2.750 | 2.500 | 1.250 | 0.125 |

| WR125-2750-1500 | 2.750 | 2.500 | 1.500 | 0.125 |

| WR125-2875-500 | 2.875 | 2.625 | 0.500 | 0.125 |

| WR125-2875-750 | 2.875 | 2.625 | 0.750 | 0.125 |

| WR125-2875-1000 | 2.875 | 2.625 | 1.000 | 0.125 |

| WR125-3000-250 | 3.000 | 2.750 | 0.250 | 0.125 |

| WR125-3000-312 | 3.000 | 2.750 | 0.312 | 0.125 |

| WR125-3000-375 | 3.000 | 2.750 | 0.375 | 0.125 |

| WR125-3000-500 | 3.000 | 2.750 | 0.500 | 0.125 |

| WR125-3000-625 | 3.000 | 2.750 | 0.625 | 0.125 |

| WR125-3000-750 | 3.000 | 2.750 | 0.750 | 0.125 |

| WR125-3000-1000 | 3.000 | 2.750 | 1.000 | 0.125 |

| WR125-3125-500 | 3.125 | 2.875 | 0.500 | 0.125 |

| WR125-3250-250 | 3.250 | 3.000 | 0.250 | 0.125 |

| WR125-3250-375 | 3.250 | 3.000 | 0.375 | 0.125 |

| WR125-3250-500 | 3.250 | 3.000 | 0.500 | 0.125 |

| WR125-3250-625 | 3.250 | 3.000 | 0.625 | 0.125 |

| WR125-3250-750 | 3.250 | 3.000 | 0.750 | 0.125 |

| WR125-3250-1000 | 3.250 | 3.000 | 1.000 | 0.125 |

| WR125-3250-1250 | 3.250 | 3.000 | 1.250 | 0.125 |

| WR125-3250-1500 | 3.250 | 3.000 | 1.500 | 0.125 |

| WR125-3250-2000 | 3.250 | 3.000 | 2.000 | 0.125 |

| WR125-3375-750 | 3.375 | 3.125 | 0.750 | 0.125 |

| WR125-3500-250 | 3.500 | 3.250 | 0.250 | 0.125 |

| WR125-3500-375 | 3.500 | 3.250 | 0.375 | 0.125 |

| WR125-3500-500 | 3.500 | 3.250 | 0.500 | 0.125 |

| WR125-3500-625 | 3.500 | 3.250 | 0.625 | 0.125 |

| WR125-3500-750 | 3.500 | 3.250 | 0.750 | 0.125 |

| WR125-3500-1000 | 3.500 | 3.250 | 1.000 | 0.125 |

| WR125-3500-1125 | 3.500 | 3.250 | 1.125 | 0.125 |

| WR125-3500-1250 | 3.500 | 3.250 | 1.250 | 0.125 |

| WR125-3500-1500 | 3.500 | 3.250 | 1.500 | 0.125 |

| WR125-3625-500 | 3.625 | 3.375 | 0.500 | 0.125 |

| WR125-3625-750 | 3.625 | 3.375 | 0.750 | 0.125 |

| WR125-3625-1000 | 3.625 | 3.375 | 1.000 | 0.125 |

| WR125-3750-250 | 3.750 | 3.500 | 0.250 | 0.125 |

| WR125-3750-375 | 3.750 | 3.500 | 0.375 | 0.125 |

| WR125-3750-500 | 3.750 | 3.500 | 0.500 | 0.125 |

| WR125-3750-625 | 3.750 | 3.500 | 0.625 | 0.125 |

| WR125-3750-750 | 3.750 | 3.500 | 0.750 | 0.125 |

| WR125-3750-1000 | 3.750 | 3.500 | 1.000 | 0.125 |

| WR125-3750-1250 | 3.750 | 3.500 | 1.250 | 0.125 |

| WR125-3750-1500 | 3.750 | 3.500 | 1.500 | 0.125 |

| WR125-3875-500 | 3.875 | 3.625 | 0.500 | 0.125 |

| WR125-3875-1000 | 3.875 | 3.625 | 1.000 | 0.125 |

| WR125-4000-250 | 4.000 | 3.750 | 0.250 | 0.125 |

| WR125-4000-375 | 4.000 | 3.750 | 0.375 | 0.125 |

| WR125-4000-500 | 4.000 | 3.750 | 0.500 | 0.125 |

| WR125-4000-625 | 4.000 | 3.750 | 0.625 | 0.125 |

| WR125-4000-750 | 4.000 | 3.750 | 0.750 | 0.125 |

| WR125-4000-1000 | 4.000 | 3.750 | 1.000 | 0.125 |

| WR125-4000-1250 | 4.000 | 3.750 | 1.250 | 0.125 |

| WR125-4000-1500 | 4.000 | 3.750 | 1.500 | 0.125 |

| WR125-4250-250 | 4.250 | 4.000 | 0.250 | 0.125 |

| WR125-4250-312 | 4.250 | 4.000 | 0.312 | 0.125 |

| WR125-4250-375 | 4.250 | 4.000 | 0.375 | 0.125 |

| WR125-4250-500 | 4.250 | 4.000 | 0.500 | 0.125 |

| WR125-4250-625 | 4.250 | 4.000 | 0.625 | 0.125 |

| WR125-4250-750 | 4.250 | 4.000 | 0.750 | 0.125 |

| WR125-4250-1000 | 4.250 | 4.000 | 1.000 | 0.125 |

| WR125-4250-1250 | 4.250 | 4.000 | 1.250 | 0.125 |

| WR125-4250-1500 | 4.250 | 4.000 | 1.500 | 0.125 |

| WR125-4500-312 | 4.500 | 4.250 | 0.312 | 0.125 |

| WR125-4500-375 | 4.500 | 4.250 | 0.375 | 0.125 |

| WR125-4500-500 | 4.500 | 4.250 | 0.500 | 0.125 |

| WR125-4500-625 | 4.500 | 4.250 | 0.625 | 0.125 |

| WR125-4500-750 | 4.500 | 4.250 | 0.750 | 0.125 |

| WR125-4500-1000 | 4.500 | 4.250 | 1.000 | 0.125 |

| WR125-4500-1250 | 4.500 | 4.250 | 1.250 | 0.125 |

| WR125-4500-1500 | 4.500 | 4.250 | 1.500 | 0.125 |

| WR125-4625-500 | 4.625 | 4.375 | 0.500 | 0.125 |

| WR125-4750-375 | 4.750 | 4.500 | 0.375 | 0.125 |

| WR125-4750-500 | 4.750 | 4.500 | 0.500 | 0.125 |

| WR125-4750-750 | 4.750 | 4.500 | 0.750 | 0.125 |

| WR125-4750-1000 | 4.750 | 4.500 | 1.000 | 0.125 |

| WR125-4750-1250 | 4.750 | 4.500 | 1.250 | 0.125 |

| WR125-4750-1500 | 4.750 | 4.500 | 1.500 | 0.125 |

| WR125-4875-500 | 4.875 | 4.625 | 0.500 | 0.125 |

| WR125-5000-375 | 5.000 | 4.750 | 0.375 | 0.125 |

| WR125-5000-500 | 5.000 | 4.750 | 0.500 | 0.125 |

| WR125-5000-625 | 5.000 | 4.750 | 0.625 | 0.125 |

| WR125-5000-750 | 5.000 | 4.750 | 0.750 | 0.125 |

| WR125-5000-1000 | 5.000 | 4.750 | 1.000 | 0.125 |

| WR125-5000-1125 | 5.000 | 4.750 | 1.125 | 0.125 |

| WR125-5000-1250 | 5.000 | 4.750 | 1.250 | 0.125 |

| WR125-5000-1750 | 5.000 | 4.750 | 1.750 | 0.125 |

| WR125-5250-500 | 5.250 | 5.000 | 0.500 | 0.125 |

| WR125-5250-625 | 5.250 | 5.000 | 0.625 | 0.125 |

| WR125-5250-750 | 5.250 | 5.000 | 0.750 | 0.125 |

| WR125-5250-1000 | 5.250 | 5.000 | 1.000 | 0.125 |

| WR125-5250-1250 | 5.250 | 5.000 | 1.250 | 0.125 |

| WR125-5250-1500 | 5.250 | 5.000 | 1.500 | 0.125 |

| WR125-5500-375 | 5.500 | 5.250 | 0.375 | 0.125 |

| WR125-5500-500 | 5.500 | 5.250 | 0.500 | 0.125 |

| WR125-5500-625 | 5.500 | 5.250 | 0.625 | 0.125 |

| WR125-5500-750 | 5.500 | 5.250 | 0.750 | 0.125 |

| WR125-5500-1000 | 5.500 | 5.250 | 1.000 | 0.125 |

| WR125-5500-1250 | 5.500 | 5.250 | 1.250 | 0.125 |

| WR125-5500-1500 | 5.500 | 5.250 | 1.500 | 0.125 |

| WR125-5625-500 | 5.625 | 5.375 | 0.500 | 0.125 |

| WR125-5750-500 | 5.750 | 5.500 | 0.500 | 0.125 |

| WR125-5750-750 | 5.750 | 5.500 | 0.750 | 0.125 |

| WR125-5750-1000 | 5.750 | 5.500 | 1.000 | 0.125 |

| WR125-5750-1500 | 5.750 | 5.500 | 1.500 | 0.125 |

| WR125-6000-375 | 6.000 | 5.750 | 0.375 | 0.125 |

| WR125-6000-500 | 6.000 | 5.750 | 0.500 | 0.125 |

| WR125-6000-625 | 6.000 | 5.750 | 0.625 | 0.125 |

| WR125-6000-750 | 6.000 | 5.750 | 0.750 | 0.125 |

| WR125-6000-1000 | 6.000 | 5.750 | 1.000 | 0.125 |

| WR125-6000-1250 | 6.000 | 5.750 | 1.250 | 0.125 |

| WR125-6000-1500 | 6.000 | 5.750 | 1.500 | 0.125 |

| WR125-6250-500 | 6.250 | 6.000 | 0.500 | 0.125 |

| WR125-6250-625 | 6.250 | 6.000 | 0.625 | 0.125 |

| WR125-6250-750 | 6.250 | 6.000 | 0.750 | 0.125 |

| WR125-6250-1000 | 6.250 | 6.000 | 1.000 | 0.125 |

| WR125-6250-1500 | 6.250 | 6.000 | 1.500 | 0.125 |

| WR125-6250-2000 | 6.250 | 6.000 | 2.000 | 0.125 |

| WR125-6500-500 | 6.500 | 6.250 | 0.500 | 0.125 |

| WR125-6500-625 | 6.500 | 6.250 | 0.625 | 0.125 |

| WR125-6500-750 | 6.500 | 6.250 | 0.750 | 0.125 |

| WR125-6500-1000 | 6.500 | 6.250 | 1.000 | 0.125 |

| WR125-6500-1250 | 6.500 | 6.250 | 1.250 | 0.125 |

| WR125-6500-1500 | 6.500 | 6.250 | 1.500 | 0.125 |

| WR125-6750-500 | 6.750 | 6.500 | 0.500 | 0.125 |

| WR125-6750-750 | 6.750 | 6.500 | 0.750 | 0.125 |

| WR125-6750-1000 | 6.750 | 6.500 | 1.000 | 0.125 |

| WR125-6750-1500 | 6.750 | 6.500 | 1.500 | 0.125 |

| WR125-7000-375 | 7.000 | 6.750 | 0.375 | 0.125 |

| WR125-7000-500 | 7.000 | 6.750 | 0.500 | 0.125 |

| WR125-7000-625 | 7.000 | 6.750 | 0.625 | 0.125 |

| WR125-7000-750 | 7.000 | 6.750 | 0.750 | 0.125 |

| WR125-7000-1000 | 7.000 | 6.750 | 1.000 | 0.125 |

| WR125-7000-1250 | 7.000 | 6.750 | 1.250 | 0.125 |

| WR125-7000-1500 | 7.000 | 6.750 | 1.500 | 0.125 |

| WR125-7250-500 | 7.250 | 7.000 | 0.500 | 0.125 |

| WR125-7250-750 | 7.250 | 7.000 | 0.750 | 0.125 |

| WR125-7250-1000 | 7.250 | 7.000 | 1.000 | 0.125 |

| WR125-7250-2000 | 7.250 | 7.000 | 2.000 | 0.125 |

| WR125-7500-625 | 7.500 | 7.250 | 0.625 | 0.125 |

| WR125-7500-750 | 7.500 | 7.250 | 0.750 | 0.125 |

| WR125-7500-1000 | 7.500 | 7.250 | 1.000 | 0.125 |

| WR125-7500-1500 | 7.500 | 7.250 | 1.500 | 0.125 |

| WR125-7750-750 | 7.750 | 7.500 | 0.750 | 0.125 |

| WR125-7750-1000 | 7.750 | 7.500 | 1.000 | 0.125 |

| WR125-8000-500 | 8.000 | 7.750 | 0.500 | 0.125 |

| WR125-8000-625 | 8.000 | 7.750 | 0.625 | 0.125 |

| WR125-8000-750 | 8.000 | 7.750 | 0.750 | 0.125 |

| WR125-8000-1000 | 8.000 | 7.750 | 1.000 | 0.125 |

| WR125-8000-1500 | 8.000 | 7.750 | 1.500 | 0.125 |

| WR125-8250-750 | 8.250 | 8.000 | 0.750 | 0.125 |

| WR125-8250-1000 | 8.250 | 8.000 | 1.000 | 0.125 |

| WR125-8250-1250 | 8.250 | 8.000 | 1.250 | 0.125 |

| WR125-8250-1500 | 8.250 | 8.000 | 1.500 | 0.125 |

| WR125-8500-500 | 8.500 | 8.250 | 0.500 | 0.125 |

| WR125-8500-750 | 8.500 | 8.250 | 0.750 | 0.125 |

| WR125-8500-1000 | 8.500 | 8.250 | 1.000 | 0.125 |

| WR125-8750-750 | 8.750 | 8.500 | 0.750 | 0.125 |

| WR125-8750-1000 | 8.750 | 8.500 | 1.000 | 0.125 |

| WR125-9000-500 | 9.000 | 8.750 | 0.500 | 0.125 |

| WR125-9000-750 | 9.000 | 8.750 | 0.750 | 0.125 |

| WR125-9000-1000 | 9.000 | 8.750 | 1.000 | 0.125 |

| WR125-9000-1500 | 9.000 | 8.750 | 1.500 | 0.125 |

| WR125-9000-2000 | 9.000 | 8.750 | 2.000 | 0.125 |

| WR125-9250-1000 | 9.250 | 9.000 | 1.000 | 0.125 |

| WR125-9500-500 | 9.500 | 9.250 | 0.500 | 0.125 |

| WR125-9500-750 | 9.500 | 9.250 | 0.750 | 0.125 |

| WR125-9500-1000 | 9.500 | 9.250 | 1.000 | 0.125 |

| WR125-9750-500 | 9.750 | 9.500 | 0.500 | 0.125 |

| WR125-9750-1000 | 9.750 | 9.500 | 1.000 | 0.125 |

| WR125-10000-500 | 10.000 | 9.750 | 0.500 | 0.125 |

| WR125-10000-750 | 10.000 | 9.750 | 0.750 | 0.125 |

| WR125-10000-1000 | 10.000 | 9.750 | 1.000 | 0.125 |

| WR125-10000-1250 | 10.000 | 9.750 | 1.250 | 0.125 |

| WR125-10000-1500 | 10.000 | 9.750 | 1.500 | 0.125 |

| WR125-10000-1750 | 10.000 | 9.750 | 1.750 | 0.125 |

| WR125-10250-1000 | 10.250 | 10.000 | 1.000 | 0.125 |

| WR125-10500-500 | 10.500 | 10.250 | 0.500 | 0.125 |

| WR125-10500-750 | 10.500 | 10.250 | 0.750 | 0.125 |

| WR125-10500-1000 | 10.500 | 10.250 | 1.000 | 0.125 |

| WR125-10500-1500 | 10.500 | 10.250 | 1.500 | 0.125 |

| WR125-11000-1000 | 11.000 | 10.750 | 1.000 | 0.125 |

| WR125-12000-1000 | 12.000 | 11.750 | 1.000 | 0.125 |

| WR125-12000-1500 | 12.000 | 11.750 | 1.500 | 0.125 |

| WR125-13000-1000 | 13.000 | 12.750 | 1.000 | 0.125 |

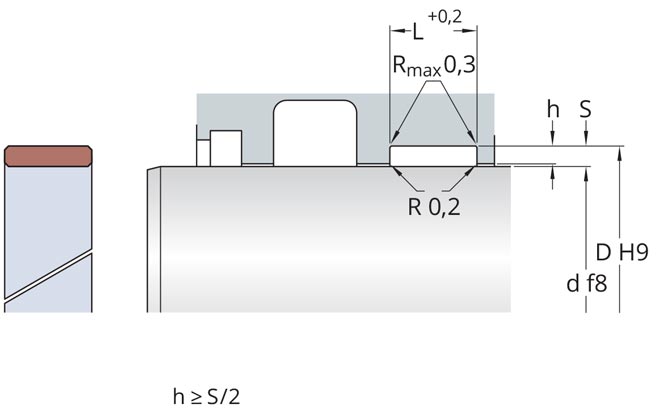

WR metric wear rings are made of a fabric reinforced phenolic resin as standard. Non-standard wear ring materials can be made to order.

Material: Phenolic/fabric composite

| Part No | Application | (D) ±H8/H9 | (d) f8 | (L) +0.2 | (S) |

|---|---|---|---|---|---|

| 2.0mm TH | |||||

| WR-32*36*20-PH | Rod | 36.0 | 32.0 | 20.0 | 2.0 |

| WR-36*40*10-PH | Rod & Piston | 40.0 | 36.0 | 10.0 | 2.0 |

| 2.5mm TH | |||||

| WR-20*25*5.6-PH | Piston | 25.0 | 20.0 | 5.6 | 2.5 |

| WR-25*30*5.6-PH | Rod & Piston | 30.0 | 25.0 | 5.6 | 2.5 |

| WR-27*32*5.6-PH | Piston | 32.0 | 27.0 | 5.6 | 2.5 |

| WR-30*35*5.6-PH | Rod & Piston | 35.0 | 30.0 | 5.6 | 2.5 |

| WR-32*37*9.7-PH | Rod | 37.0 | 32.0 | 9.7 | 2.5 |

| WR-35*40*5.6-PH | Rod & Piston | 40.0 | 35.0 | 5.6 | 2.5 |

| WR-35*40*9.7-PH | Rod & Piston | 40.0 | 35.0 | 9.7 | 2.5 |

| WR-36*41*5.6-PH | Rod | 41.0 | 36.0 | 5.6 | 2.5 |

| WR-36*41*9.7-PH | Rod | 41.0 | 36.0 | 9.7 | 2.5 |

| WR-40*45*5.6-PH | Rod & Piston | 45.0 | 40.0 | 5.6 | 2.5 |

| WR-40*45*9.7-PH | Rod | 45.0 | 40.0 | 9.7 | 2.5 |

| WR-45*50*5.6-PH | Rod & Piston | 50.0 | 45.0 | 5.6 | 2.5 |

| WR-45*50*9.7-PH | Rod & Piston | 50.0 | 45.0 | 9.7 | 2.5 |

| WR-50*55*5.6-PH | Rod & Piston | 55.0 | 50.0 | 5.6 | 2.5 |

| WR-50*55*9.7-PH | Rod & Piston | 55.0 | 50.0 | 9.7 | 2.5 |

| WR-50*55*15-PH | Rod | 55.0 | 50.0 | 15.0 | 2.5 |

| WR-55*60*5.6-PH | Rod & Piston | 60.0 | 55.0 | 5.6 | 2.5 |

| WR-55*60*9.7-PH | Rod & Piston | 60.0 | 55.0 | 9.7 | 2.5 |

| WR-56*61*5.6-PH | Rod | 61.0 | 56.0 | 5.6 | 2.5 |

| WR-56*61*9.7-PH | Rod | 61.0 | 56.0 | 9.7 | 2.5 |

| WR-58*63*5.6-PH | Piston | 63.0 | 58.0 | 5.6 | 2.5 |

| WR-58*63*9.7-PH | Piston | 63.0 | 58.0 | 9.7 | 2.5 |

| WR-60*65*5.6-PH | Rod & Piston | 65.0 | 60.0 | 5.6 | 2.5 |

| WR-60*65*9.7-PH | Rod & Piston | 65.0 | 60.0 | 9.7 | 2.5 |

| WR-60*65*15-PH | Rod | 65.0 | 60.0 | 15.0 | 2.5 |

| WR-63*68*5.6-PH | Rod | 68.0 | 63.0 | 5.6 | 2.5 |

| WR-63*68*9.7-PH | Rod | 68.0 | 63.0 | 9.7 | 2.5 |

| WR-65*70*5.6-PH | Piston | 70.0 | 65.0 | 5.6 | 2.5 |

| WR-65*70*9.7-PH | Rod & Piston | 70.0 | 65.0 | 9.7 | 2.5 |

| WR-65*70*20-PH | Piston | 70.0 | 65.0 | 20.0 | 2.5 |

| WR-70*75*5.6-PH | Piston | 75.0 | 70.0 | 5.6 | 2.5 |

| WR-70*75*9.7-PH | Rod & Piston | 75.0 | 70.0 | 9.7 | 2.5 |

| WR-75*80*5.6-PH | Piston | 80.0 | 75.0 | 5.6 | 2.5 |

| WR-75*80*9.7-PH | Rod & Piston | 80.0 | 75.0 | 9.7 | 2.5 |

| WR-75*80*15-PH | Piston | 80.0 | 75.0 | 15.0 | 2.5 |

| WR-80*85*5.6-PH | Piston | 85.0 | 80.0 | 5.6 | 2.5 |

| WR-80*85*9.7-PH | Rod & Piston | 85.0 | 80.0 | 9.7 | 2.5 |

| WR-80*85*15-PH | Rod | 85.0 | 80.0 | 15.0 | 2.5 |

| WR-85*90*5.6-PH | Piston | 90.0 | 85.0 | 5.6 | 2.5 |

| WR-85*90*9.7-PH | Rod & Piston | 90.0 | 85.0 | 9.7 | 2.5 |

| WR-85*90*15-PH | Rod | 90.0 | 85.0 | 15.0 | 2.5 |

| WR-90*95*9.7-PH | Rod & Piston | 95.0 | 90.0 | 9.7 | 2.5 |

| WR-90*95*15-PH | Rod | 95.0 | 90.0 | 15.0 | 2.5 |

| WR-95*100*9.7-PH | Rod & Piston | 100.0 | 95.0 | 9.7 | 2.5 |

| WR-95*100*15-PH | Rod | 100.0 | 95.0 | 15.0 | 2.5 |

| WR-100*105*9.7-PH | Rod | 105.0 | 100.0 | 9.7 | 2.5 |

| WR-100*105*15-PH | Rod | 105.0 | 100.0 | 15.0 | 2.5 |

| WR-105*110*9.7-PH | Piston | 110.0 | 105.0 | 9.7 | 2.5 |

| WR-105*110*15-PH | Piston | 110.0 | 105.0 | 15.0 | 2.5 |

| WR-110*115*9.7-PH | Rod & Piston | 115.0 | 110.0 | 9.7 | 2.5 |

| WR-110*115*15-PH | Rod | 115.0 | 110.0 | 15.0 | 2.5 |

| WR-115*120*9.7-PH | Piston | 120.0 | 115.0 | 9.7 | 2.5 |

| WR-120*125*9.7-PH | Rod & Piston | 125.0 | 120.0 | 9.7 | 2.5 |

| WR-120*125*15-PH | Rod | 125.0 | 120.0 | 15.0 | 2.5 |

| WR-125*130*9.7-PH | Rod & Piston | 130.0 | 125.0 | 9.7 | 2.5 |

| WR-125*130*15-PH | Rod | 130.0 | 125.0 | 15.0 | 2.5 |

| WR-130*135*9.7-PH | Rod | 135.0 | 130.0 | 9.7 | 2.5 |

| WR-130*135*15-PH | Rod | 135.0 | 130.0 | 15.0 | 2.5 |

| WR-135*140*9.7-PH | Piston | 140.0 | 135.0 | 9.7 | 2.5 |

| WR-135*140*15-PH | Piston | 140.0 | 135.0 | 15.0 | 2.5 |

| WR-140*145*15-PH | Rod | 145.0 | 140.0 | 15.0 | 2.5 |

| WR-145*150*9.7-PH | Piston | 150.0 | 145.0 | 9.7 | 2.5 |

| WR-145*150*15-PH | Piston | 150.0 | 145.0 | 15.0 | 2.5 |

| WR-150*155*15-PH | Rod | 155.0 | 150.0 | 15.0 | 2.5 |

| WR-155*160*9.7-PH | Piston | 160.0 | 155.0 | 9.7 | 2.5 |

| WR-155*160*15-PH | Piston | 160.0 | 155.0 | 15.0 | 2.5 |

| WR-160*165*9.7-PH | Rod | 165.0 | 160.0 | 9.7 | 2.5 |

| WR-160*165*15-PH | Rod | 165.0 | 160.0 | 15.0 | 2.5 |

| WR-165*170*15-PH | Piston | 170.0 | 165.0 | 15.0 | 2.5 |

| WR-175*180*9.7-PH | Piston | 180.0 | 175.0 | 9.7 | 2.5 |

| WR-175*180*15-PH | Piston | 180.0 | 175.0 | 15.0 | 2.5 |

| WR-180*185*15-PH | Rod | 185.0 | 180.0 | 15.0 | 2.5 |

| WR-185*190*15-PH | Piston | 190.0 | 185.0 | 15.0 | 2.5 |

| WR-195*200*9.7-PH | Piston | 200.0 | 195.0 | 9.7 | 2.5 |

| WR-195*200*15-PH | Piston | 200.0 | 195.0 | 15.0 | 2.5 |

| WR-195*200*20-PH | Piston | 200.0 | 195.0 | 20.0 | 2.5 |

| WR-200*205*15-PH | Rod | 205.0 | 200.0 | 15.0 | 2.5 |

| WR-205*210*15-PH | Piston | 210.0 | 205.0 | 15.0 | 2.5 |

| WR-215*220*15-PH | Piston | 220.0 | 215.0 | 15.0 | 2.5 |

| WR-220*225*15-PH | Rod | 225.0 | 220.0 | 15.0 | 2.5 |

| WR-220*225*25-PH | Rod | 225.0 | 220.0 | 25.0 | 2.5 |

| WR-225*230*15-PH | Piston | 230.0 | 225.0 | 15.0 | 2.5 |

| WR-235*240*9.7-PH | Piston | 240.0 | 235.0 | 9.7 | 2.5 |

| WR-235*240*15-PH | Piston | 240.0 | 235.0 | 15.0 | 2.5 |

| WR-245*250*15-PH | Piston | 250.0 | 245.0 | 15.0 | 2.5 |

| WR-255*260*15-PH | Piston | 260.0 | 255.0 | 15.0 | 2.5 |

| WR-275*280*15-PH | Piston | 280.0 | 275.0 | 15.0 | 2.5 |

| WR-275*280*25-PH | Piston | 280.0 | 275.0 | 25.0 | 2.5 |

| WR-295*300*15-PH | Piston | 300.0 | 295.0 | 15.0 | 2.5 |

| WR-295*300*25-PH | Piston | 300.0 | 295.0 | 25.0 | 2.5 |

| 3.0mm TH | |||||

| WR-40*46*10-PH | Rod | 46.0 | 40.0 | 10.0 | 3.0 |

| WR-40*46*20-PH | Rod | 46.0 | 40.0 | 20.0 | 3.0 |

| WR-74*80*20-PH | Piston | 80.0 | 74.0 | 20.0 | 3.0 |

| WR-74*80*25-PH | Piston | 80.0 | 74.0 | 25.0 | 3.0 |

| WR-80*86*25-PH | Rod | 86.0 | 80.0 | 25.0 | 3.0 |

| WR-80*86*30-PH | Rod | 86.0 | 80.0 | 30.0 | 3.0 |

| WR-80*86*40-PH | Rod | 86.0 | 80.0 | 40.0 | 3.0 |

| WR-84*90*20-PH | Piston | 90.0 | 84.0 | 20.0 | 3.0 |

| WR-90*96*30-PH | Rod | 96.0 | 90.0 | 30.0 | 3.0 |

| WR-94*100*13-PH | Piston | 100.0 | 94.0 | 13.0 | 3.0 |

| WR-94*100*20-PH | Piston | 100.0 | 94.0 | 20.0 | 3.0 |

| WR-94*100*25-PH | Piston | 100.0 | 94.0 | 25.0 | 3.0 |

| WR-94*100*30-PH | Piston | 100.0 | 94.0 | 30.0 | 3.0 |

| WR-104*110*30-PH | Piston | 110.0 | 104.0 | 30.0 | 3.0 |

| WR-114*120*30-PH | Piston | 120.0 | 114.0 | 30.0 | 3.0 |

| WR-118*121*20-PH | Rod | 121.0 | 115.0 | 20.0 | 3.0 |

| WR-119*125*15-PH | Piston | 125.0 | 119.0 | 15.0 | 3.0 |

| WR-119*125*20-PH | Piston | 125.0 | 119.0 | 20.0 | 3.0 |

| WR-119*125*25-PH | Piston | 125.0 | 119.0 | 25.0 | 3.0 |

| WR-119*125*30-PH | Piston | 125.0 | 119.0 | 30.0 | 3.0 |

| WR-124*130*13-PH | Piston | 130.0 | 124.0 | 13.0 | 3.0 |

| WR-124*130*30-PH | Piston | 130.0 | 124.0 | 30.0 | 3.0 |

| WR-134*140*20-PH | Piston | 140.0 | 134.0 | 20.0 | 3.0 |

| WR-134*140*30-PH | Piston | 140.0 | 134.0 | 30.0 | 3.0 |

| WR-144*150*20-PH | Piston | 150.0 | 144.0 | 20.0 | 3.0 |

| WR-154*160*15-PH | Piston | 160.0 | 154.0 | 15.0 | 3.0 |

| WR-154*160*30-PH | Piston | 160.0 | 154.0 | 30.0 | 3.0 |

| WR-154*160*35-PH | Piston | 160.0 | 154.0 | 35.0 | 3.0 |

| WR-154*160*50-PH | Piston | 160.0 | 154.0 | 50.0 | 3.0 |

| WR-174*180*30-PH | Piston | 180.0 | 174.0 | 30.0 | 3.0 |

| WR-194*200*20-PH | Piston | 200.0 | 194.0 | 20.0 | 3.0 |

| WR-244*250*19.5-PH | Piston | 250.0 | 244.0 | 19.5 | 3.0 |

| 4.0mm TH | |||||

| WR-172*180*40-PH | Piston | 180.0 | 172.0 | 40.0 | 4.0 |

| WR-192*200*25-PH | Piston | 200.0 | 192.0 | 25.0 | 4.0 |

| WR-242*250*20-PH | Piston | 250.0 | 242.0 | 20.0 | 4.0 |

| WR-242*250*25-PH | Piston | 250.0 | 242.0 | 25.0 | 4.0 |

| WR-272*280*25-PH | Piston | 280.0 | 272.0 | 25.0 | 4.0 |

| WR-292*300*20-PH | Piston | 300.0 | 292.0 | 20.0 | 4.0 |

| WR-292*300*25-PH | Piston | 300.0 | 292.0 | 25.0 | 4.0 |

Wear strip is essentially wear ring material of a standard width and thickness that is cut to length. Wear strip is available in 40% bronze filled Teflon and fabric / polyester resin. Please contact us for information on available sizes and materials.

HOURS OF OPERATION • AEST Monday to Thursday 8.30 am – 5.30 pm